Traditional enterprises in manufacturing logistics and warehousing logistics are faced with problems such as difficulty in recruiting workers, high labor costs, labor safety hazards, etc., as well as additional management costs and risks. The use of robots can effectively avoid these problems.

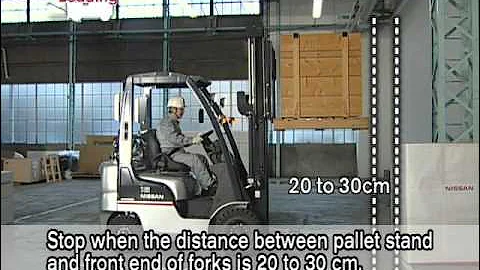

Counterbalanced unmanned forklift is one of the most widely used forklifts. It can not only meet the needs of stacking operations, but also has the advantages of fast running speed, good climbing ability and high load limit. It is also suitable for Tianzi pallets, The automated transfer and handling of palletized goods such as Sichuan pallets between different cargo spaces has a wide range of applications, such as: unmanned loading and unloading trucks, ground cargo stacking, shuttle rack docking, ground horizontal handling, heavy-duty stacking and other application scenarios.

MW-SE20

Counterbalanced unmanned forklift

MW-SE12

MW-E series

In the production workshop, in the raw material and finished product warehouse, there are many types of materials and heavy weights. Materials need to be distributed to various production lines frequently and efficiently. Manual forklifts exist for cargo transportation. There are major safety risks, and it is impossible to realize the intelligence and informatization of logistics and transportation. With the expansion of production scale, manual work alone can no longer meet production requirements.

counterbalanced unmanned forklift can easily meet the requirements of high-load, indoor + outdoor all-scene high-efficiency operations. Currently, the micro-counterbalanced unmanned forklift solution has been widely used in production lines in food, medicine, automobiles, metallurgy and other industries. Typical scenarios of bargeing, warehousing and distribution, as well as complex scenarios such as cargo stacking and high-precision docking in warehouses.

Food industry

—

Intelligent warehousing + Intelligent production line

1

Counterbalanced unmanned forklift + Production line interconnection + 6-layer wooden frame stacking + Automatic door/automatic charging equipment

Product selection: Counterbalanced unmanned forklift MW- L12AC

System configuration: Scheduling system RCS + Equipment control system WCS + Warehouse management system WMS

Project introduction

· A modern agricultural enterprise integrating "ecology, leisure, sightseeing and tourism"

· Handling materials: fresh fruits

· Project scene: Fruit loading workshop → Automatic connection and turnover in fresh-keeping warehouse

· Handling process: fruit loading machine → stacking area → fresh-keeping warehouse (single stack is 6 stories high)

Customer pain points

Pain point 1: Low operating efficiency

Relying on purely manual operations, goods picking Slow down, easy to make mistakes when picking up and placing goods;

Pain point 2: The docking accuracy is not high

Stacking wooden boxes requires high precision, and manual work is labor-intensive;

Pain point 3: Inventory management is disordered

Fresh cache warehouse and inventory information cannot be effectively obtained Control;

Pain point 4: The impact of cargo damage is serious.

The standardization of manual work cannot be supervised, and the rate of fresh fruit damage is high;

Pain point 5: The cost investment is large.

Harvest production time is concentrated, and it is difficult to temporarily recruit forklift workers.

Project value

In this project, micro-robots helped the agricultural product company successfully achieve accurate and effective stacking of wooden frames, improve warehouse utilization, and ensure stacking safety; significantly reduce the labor intensity of workers, improve the efficiency of handling goods; and reduce the impact on the floor of the production workshop The second transformation improves the overall flexibility; realizes material distribution information linkage and paperless information data traceability; the entire process is automated, and the production line process is greatly optimized.

2

Counterbalanced unmanned forklift + warehouse docking + cluster dispatch + Sky Eye system

Product selection: Counterbalanced unmanned forklift MW-L08AC

System configuration: Scheduling system RCS + Warehouse management system WMS + Sky Eye system

Project introduction

· A Chinese company The No. 1 brand in the field of FMCG food (jelly, pudding and seaweed)

· Handling materials: FMCG food

· Project scenario: Automatic or manual palletizing of finished products into the warehouse

Customer pain points

Pain point 1: Low collaboration efficiency

Involving transportation Lines and elevators are jointly connected, and manual efficiency is low.

Pain point 2: The docking accuracy is not high.

Stacking wooden boxes requires high accuracy, and manual work is labor-intensive.

Pain point 3: The appearance monitoring is disordered.

Manual palletizing is highly arbitrary and the appearance is unqualified. Returning is time-consuming and laborious;

Pain point 4: Large fluctuations in off-peak and peak seasons

There is a large traffic gap in off-peak and peak seasons, making it difficult to unify resource allocation;

Pain point 5: Large cost investment

Three shifts, repetitive and ineffective walking operations, and costs rising year after year.

Project value

In this project, micro-robots helped the fast-moving consumer goods company successfully implement system WCS collaborative docking of conveyor lines and elevators to improve handling efficiency; realize unmanned handling, reduce labor costs, and machines replace labor; machines replace labor , high palletizing accuracy, improving efficiency; 24-hour non-stop operation, effectively meeting peak cargo handling requirements; using high areas in the warehouse to increase storage density and storage capacity.

Automotive industry—

Intelligent production line

3

Counterbalanced unmanned forklift + 6-layer material rack stacking + Sky Eye system

Product selection: Counterbalanced unmanned forklift MW-SE20, MW-SE30

System configuration: Scheduling system RCS + warehouse management System WMS + Sky Eye System

· Affiliated to a large Japanese auto parts (automatic transmission) production group

· Handling materials: transmission

· Project scenario: Automated warehousing, palletizing and depalletizing of finished products off the production line

Customer Pain point

Pain point 1: Inventory management is disordered

Material information linkage cannot be achieved and cannot be effectively controlled;

Pain point 2: Labor intensity is high

Palletizing requirements are high (6-layer palletizing), and manual labor intensity is high;

Pain point 3: Cost The investment is large and

24h operates non-stop, and the cost of labor input remains high.

Project value

The company finally adopted the counterbalanced unmanned forklift MW-SE20 model with a load capacity of 2T, which can effectively meet the requirements of high precision, high lifting height and load capacity for palletizing in auto parts production plants. And through the micro-robot self-developed dispatching system RCS, equipment control system WCS, and warehouse management system WMS, it realizes equipment interconnection, data interoperability, warehouse location visualization, and comprehensive control of vehicle operating status, and supports coordinated dispatching of multiple models and multiple models. A kind of hybrid warehouse management and multi-device system module integration realize system intelligence and storage optimization in the field.

Pharmaceutical industry

—

Intelligent warehousing

4

Counterbalanced unmanned forklift + lights-out warehouse + finished product incoming and outgoing warehousing

Product selection: Counterbalanced unmanned forklift MW-LD-L06AC

System configuration: Scheduling system RCS + Warehouse management system WMS

Project introduction

· A large state-owned medical device manufacturer, affiliated to Tianjin Pharmaceutical Group

· Handling materials: medical devices, drugs

· Project scenario: 4.2-meter-high beam-type shelves in and out of warehouse

Customer pain points

Pain point 1: Difficulty in recruitment

Location Located in the suburbs of northern cities, the work is single and recruitment is difficult;

Pain point 2: low operating efficiency

The manual mode has low timeliness in matching physical logistics and information flow;

Pain point 3: disordered information management

The cargo information of drugs and medical devices cannot be effectively controlled;

Pain point 4: Warehouse capacity is wasted

The floor is stacked flat, and the space cannot be effectively used.

Project value

This project needs to overcome many difficulties. Black pallets need to be identified in the factory when the lights are turned off, and the shelves are beam-type shelves with a height of 4.2 meters. The traditional manual operation mode cannot meet the accuracy requirements of warehouse handling. With the support of technologies such as pallet posture recognition and high-level shelf stacking, Miwei's flexible vision solution enables accurate forking of goods of multiple specifications at each station, effectively manages cargo information, and greatly improves warehousing utilization efficiency and handling efficiency.

Metallurgical industry

—

Intelligent production line

5

Counterbalanced unmanned forklift + 2T load capacity + high-precision loading and unloading

Product selection: Counterbalanced unmanned forklift MW-E30

System configuration: Scheduling system RCS + warehouse management system WMS + equipment control System WCS

Project Introduction

· A well-known domestic steel group, a modern large-scale steel vanadium and titanium enterprise group

· Project scene: finished product production workshop

· Handling materials: finished product hopper (2000kg)

· Handling process: kiln unloading area - heavy hopper area —Empty bucket area—Kiln discharge area

Customer pain points

Pain point 1: Big physiological challenges

Metal dust is produced in the air, and the working environment of personnel is harsh;

Pain point 2: High cost investment

Difficulty in recruitment, repetitive manual work, labor The cost remains high;

Pain point 3: The impact of cargo damage is serious.

The standardization of manual work is difficult to supervise, and the cargo damage is relatively serious;

Pain point 4: Future planning of the factory.

is committed to realizing fully automated flexible production line intelligent manufacturing and logistics upgrades.

Project value

In metallurgical factories with harsh environments, how to improve the efficiency of handling large-ton goods is the key. This project uses the hydraulic large counterbalanced unmanned forklift, which has a load capacity of 5 tons and a speed of 2.6m/s. The project gives full play to the advantages of the self-developed system, which is extremely stable and cost-effective. With the support of the dispatching system RCS and the on-site management system WMS, it can be connected with various equipment during the transportation process, improving the transportation efficiency and realizing the visualization of on-site inventory information. , digital management, automatic charging, automatic and uninterrupted operation throughout the day, greatly improving efficiency and saving labor costs.

The "giant" is riding on the wind and taking advantage of the opportunities of the era in smart manufacturing. As a builder of smart logistics infrastructure, Miwei is driven by technology and develops its own core hardware & algorithms. It is an integrated solution with both cost and performance advantages in the industry. As one of the solution providers, it has implemented many benchmark projects in production line logistics, warehousing logistics and other scenarios in the food, medicine, automobile, new energy and other industries, and has become a trusted partner of many industry-leading customers.