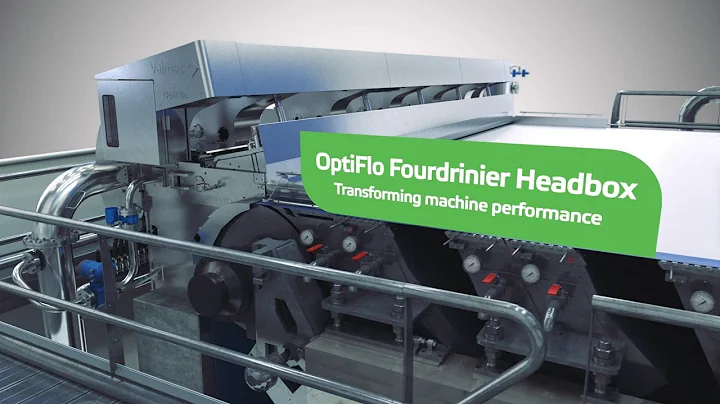

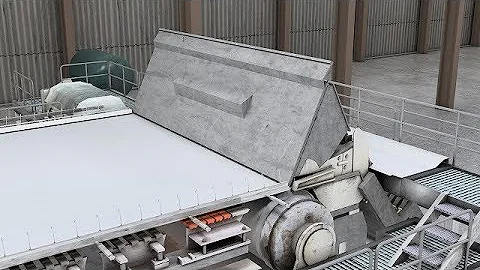

Recently, Dongguan Shanglong Paper’s 4800/650 single-layer web corrugated paper machine transformation project was successfully started. This production line uses a dilution water hydraulic headbox designed and manufactured by Hangzhou Meichen Paper Technology Co., Ltd. The headbox has a spray width of 5250mm and a vehicle speed of 650m/min. The smooth start-up of the project is inseparable from the close cooperation between Dongguan Shanglong and Meichen and the market's full trust in Meichen's headbox. This transformation has greatly improved production efficiency and product quality, and has been well received by customers.

About Shanglong:

Dongguan Shanglong Paper Co., Ltd. was established in 2007. The company is located in the Beihai Zai Paper Industry Base, Huangyong Industrial Park, Zhongtang Town, Dongguan City, Guangdong Province. The company is constructed in two phases. The first phase of the project passed through Dongguan With the approval of the Municipal Environmental Protection Bureau, the annual production scale of high-strength corrugated paper and kraft liner paper is 400,000 tons. It is allowed to set up three 4600 paper machines, one 130T/H boiler, one 15000KW steam turbine, and one 18000KW generator set. tower. It passed the acceptance inspection of Dongguan Municipal Environmental Protection Bureau on December 15, 2010. The factory currently has 450 employees, including more than 30 senior talents, 41 internationally certified senior engineers, 10 engineers, 6 professional technicians, and 31 certified special staff (boilers, electrical, instruments, machinery). The annual output reaches 250,000 tons, and the annual output value is approximately 500 million

. The first phase of the project invested 380 million

, of which 21 million

was invested to build a large-scale sewage treatment system matching the existing production line. Using internationally advanced biochemical + physical and chemical treatment processes, the daily sewage treatment capacity reached 12,000 tons; in order to reduce To prevent atmospheric pollution, the company is equipped with a clean circulating vulcanized bed coal-fired boiler and a complete dust removal and desulfurization system. The dust removal efficiency reaches more than 99.7% and the desulfurization efficiency reaches more than 90%.

About Huazhang:

Huazhang Technology (HK01673) was founded in 1993 and is a technology-based enterprise listed in Hong Kong. With more than 20 years of experience in papermaking electrical automation, headboxes and formers, environmental protection equipment and engineering, it is China's leading technology company Provider of solutions, equipment and comprehensive services to the paper industry. We focus on the technological progress and quality improvement of papermaking equipment. Over the past 20 years, we have completed more than 2,000 engineering projects, providing papermaking enterprises with factory services based on "intelligent manufacturing", " green manufacturing " and "project general contracting" equipment and services, aiming to become a full-time "nanny" for the papermaking industry. In the face of new historical opportunities, we advocate the concept of "integration, co-creation, and sharing" to jointly welcome the bright future of the papermaking equipment industry.

About Meichen:

company was founded in 2001. After years of hard work, it has developed into a professional R&D and manufacturing enterprise of key papermaking equipment. It provides papermaking enterprises with various products related to papermaking and molding, such as solution design, new product matching, old machine transformation, debugging and maintenance, etc. Services. The company's products include the following series:

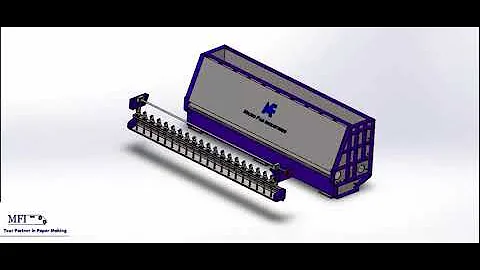

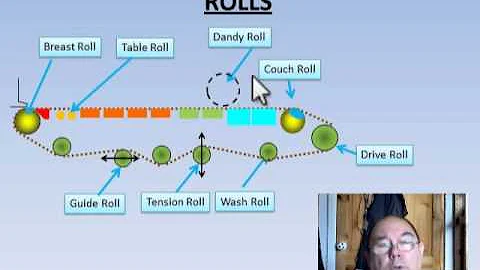

◆Headbox: full flow hydraulic headbox, open/air cushion type homogenizer roller headbox, turbulent channel headbox, ultra-low speed headbox, crescent forming Former headbox, high-quantity cardboard headbox, vacuum rotary screen headbox, various types of rotary screen troughs, special headbox for Fourdrinier household paper, inclined screen former headbox, etc.

◆Automated control system. : Headbox computer total pressure/liquid level control system, automatic lip plate quantitative adjustment system, automatic dilution water horizontal quantitative condition adjustment system.

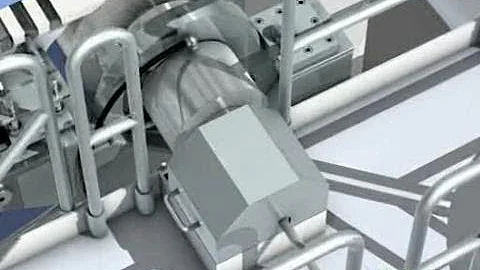

◆Former: inclined screen former, vacuum rotary screen former, composite vacuum roller forming

◆Forming assistance: non-reaction force high-frequency shaking machine, steam humidifier, former optimization and transformation, etc.