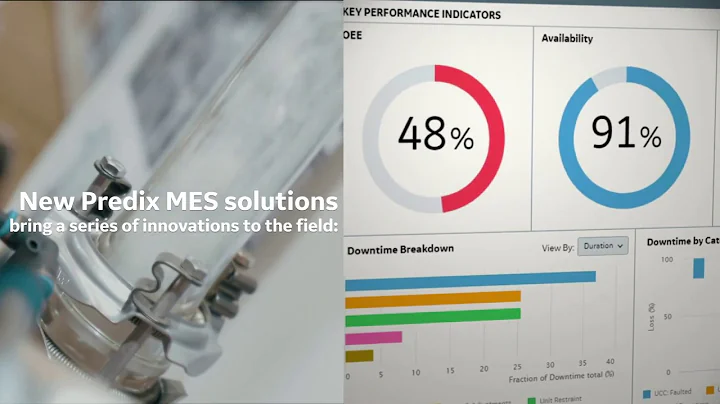

Equipment networking is commonly referred to as equipment information transformation (MES), which helps to improve the level of enterprise informationization and realize the upgrading of the manufacturing industry. There are many more benefits it brings to enterprises that need not be described here.

PLC networking is the top priority for equipment informatization. In short, PLC realizes centralized monitoring and management of data through Ethernet .

Most of the early PLCs only have serial port . So, what problems will these PLCs encounter during the networking process?

With many years of field experience, the following items are not easy to ignore:

(1) The serial port is exclusively occupied by the human-machine interface (touch screen);

(2) The PLC program is encrypted;

(3) Modification of the PLC program and hardware is not allowed Configuration;

(4) does not allow downtime to avoid impact on production;

(5) is best compatible with the PLC's Ethernet protocol (different from the serial port server virtual serial port).

These problems are simply too annoying. Is there any good solution?

With these questions, let’s look at a case.

In a semiconductor manufacturing company, about 300 Mitsubishi FX1N/FX2N controllers need to be connected to the network. The programming round ports MD8 of these PLCs are all connected to a domestic human-machine interface.

Engineers who are familiar with Mitsubishi all know that the early Mitsubishi PLC did not produce Ethernet modules. The equipment must be connected to the Ethernet, and there are few options...

The factory also has some Siemens , Omron , Panasonic , Delta equipment also encountered similar problems.

The key to solving the problem is to convert the serial port to Ethernet and be compatible with the Ethernet protocol of the corresponding PLC.

In this regard, we might as well look at an artifact:

The model of the artifact is BCNet-FX, which is used for device networking of Mitsubishi FX series PLCs. With this artifact, the above problems are easily solved.

Take a closer look. The serial interface X1 is connected to the programming round port of Mitsubishi PLC. The serial interface X2 is connected to the touch screen (this touch screen was originally plugged into the programming round port of Mitsubishi PLC). The Ethernet communication interface X3 is compatible with Mitsubishi MC protocol and Modbus TCP protocol.

BCNet-FX is installed on the 35mm rail and takes power through the PLC round port, without the need for external power supply .

Mitsubishi PLC programming software such as GX Works2, SCADA software such as force control, Kingview , MCGS, Jiecon, WinCC, etc., OPC server such as KEPSERVER, high-level languages such as VC, C#, etc. can be used through Mitsubishi MC protocol or Modbus TCP server to access BCNet-FX.

In this sense, BCNet-FX is equivalent to the Ethernet expansion unit of FX3U.

BCNet-FX function:

- is installed on a 35mm rail, no external power supply is required. The X1 port is connected to the FX's MD8 programming communication port, and the X2 expansion port is used for touch screen communication.

- can set parameters and run diagnosis on the device through WEB server or configuration diagnostic tool BCDevice.

- automatically adjusts the baud rate of the FX programming communication port, which can adapt to the needs of large data volume communication.

- supports Ethernet communication of MELSOFT products (GX Works2, GX Developer, etc.).

- supports host computer MC Ethernet protocol (MELSEC Communication Protocol) communication, and supports access by host software (Kingview, MCGS, Force Control, IFIX, INTOUCH, KepWare OPC server, etc.).

- integrates ModbusTCP server, supports FC1, FC2, FC3, FC5, FC6, FC16, and the Modbus data area is automatically mapped to the FX data area.

- adopts MC communication protocol, which can realize high-level language (such as VB, VC, C#, etc.) programming, realize data communication with Mitsubishi FX, and facilitate the development of production management systems.

- supports OPC channel SCADA (upper-level configuration software) to communicate with FX in OPC mode.

- can simultaneously realize MELSOFT connection, MC protocol connection, and ModbusTCP connection. Supports 6 host computer connections.

- supports firmware updates on the user side through Ethernet. Purchase once and upgrade permanently.

Let’s take a look at other PLCs:

BCNet-S7200

(Siemens PPI to Ethernet)

BCNet-S7300 Plus

(Siemens MPI/PROFIBUS to Ethernet)

BCNet-Q

(Mitsubishi Q series access to Ethernet)

BCNet-CP

(Omron CP1E /CP1H connects to Ethernet)

BCNet-FP

(Panasonic FP2SH connects to Ethernet)

BCNet-DVP

(Delta DVP connects to Ethernet)

Appendix:

Forwarding is the greatest encouragement! Thank you for your support!

Tips

PLC exclusive materials: contains all PLC learning materials from entry to advanced in (Mitsubishi/Siemens/Omron) , 18 encyclopedias of electrical classics, past electrical examination papers, essential electrical training simulation software, electrical Various types of technical manuals for the automated industry!

![Intro to Manufacturing Operations, Technology, and Processes [The Most Important Things to Know] - DayDayNews](https://i.ytimg.com/vi/zR36urTYC4k/hq720.jpg?sqp=-oaymwEcCNAFEJQDSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLCUA-CDEFkcX5rOu06JOysWwwBwbA)