Currently, French rail transit company Alstom is cooperating with Replique, a subsidiary of chemical company BASF, to produce spare parts for trains through 3D printing technology.

To successfully carry out this project, Replique had earlier collaborated with Miele to establish a materials alliance. Alstom has digitized some spare parts of the train. It uses 3D scanning, modeling and other methods to create three-dimensional model data of these parts and establish a database, which makes it convenient for train maintenance teams everywhere to flexibly print out various spare parts. In addition, this project also uses wire extrusion technology, which is likely to be the first time this technology has been applied to the manufacture of train spare parts.

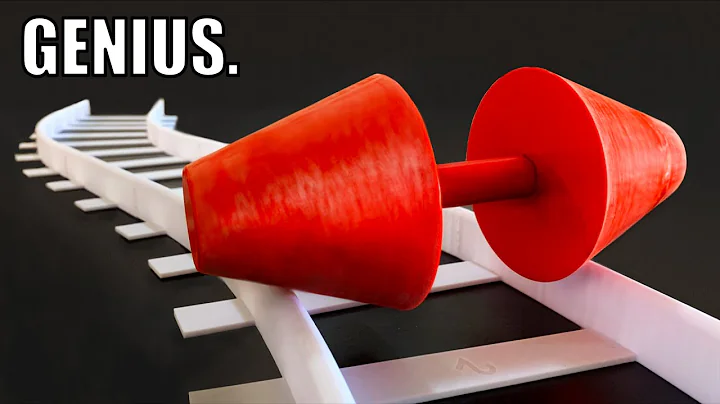

Metal wire extrusion technology is similar to the most common FDM 3D printing technology, except that the material is changed from PLA and other plastic wires to metal wires. The advantages of this technology are fast printing speed and low price; the disadvantage is that the surface of the printed parts is relatively rough and requires sintering to increase strength, as well as post-processing such as grinding and polishing. However, as the level of integration increases (printing, sintering, milling, grinding and other functions are integrated into one set of equipment), the application of wire extrusion technology is gradually increasing.

For this project, the two companies used an aluminum alloy wire that combined material extrusion 3D printing and sintering to make the part very low-cost.