Follow the WeChat official account: Procurement and supply chain learning platform (receive procurement and supply chain learning materials and common office forms)!

2,

Why choose to do purchasing?

Answer: A can familiarize yourself with the commodity market and increase your knowledge. B. You can get in touch with different people, improve your language communication skills, and enhance your personal charm. C. Secondly, it is not easy to do a good job in purchasing. There is a lot of room for personal development, which is very helpful for personal development. Purchasing pressure - how to use cost structure as a guide to ensure that goods are purchased at the lowest cost.

3,

What is the procurement process?

Answer: Collect information, inquire, compare prices, negotiate, evaluate, request samples, decide, requisition, order, coordinate and communicate, expedite delivery, incoming goods inspection, and payment.

4,

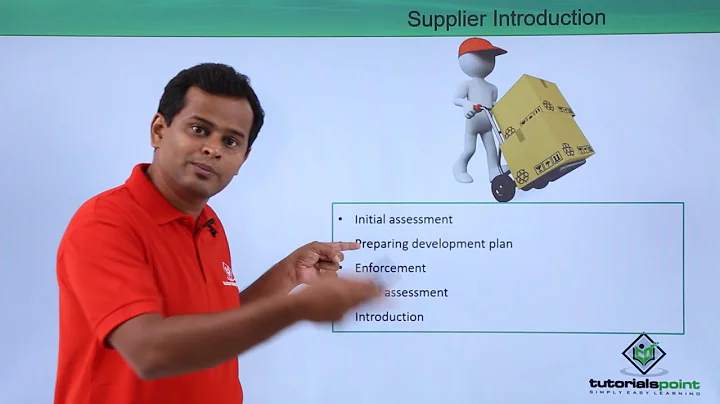

How should buyers develop new suppliers?

Answer: Each company has its own process for developing suppliers. Generally speaking, it first collects supplier information online, exhibitions, friend introductions, supplier self-recommendations, etc. - proceed Supplier questionnaire implementation survey - evaluation - supplier sample delivery - qualified - listed as qualified supplier; if not qualified, search again.

5,

What responsibilities do buyers have to bear?

Answer: Procurement planning and demand confirmation, supplier selection and management, procurement quantity control, procurement quality control, procurement price control, delivery time control, procurement cost control, procurement contract management, Procurement record management.

6,

The customer suddenly canceled the order, and the materials returned to the factory. The supplier does not agree to return the goods and cannot claim compensation from the customer?

Answer: Usually this situation rarely happens in the procurement industry, because you have signed a contract with the customer. You have also signed a series of contracts with your supplier. When a customer suddenly cancels an order, it does not mean that the customer just cancels the order without giving any processing method. Generally speaking, the customer will definitely give Some of your handling methods, such as: It will take a certain amount of time to find a new buyer for this batch of goods. Therefore, at this time, generally speaking, the customer verbally says that he wants to find a new buyer, but the time does not wait. You We can only find ways to help customers through various channels and communicate with suppliers appropriately.

7,

What is the cost of the company’s products?

Answer: Raw material cost + manufacturing cost, water and electricity, labor, maintenance, packaging, inspection, machine depreciation, reporting and other management expenses + tax + profit + transportation

8.

How to let the company and suppliers work together Development? Talk about your views on procurement strategy?

Answer: This question is relatively big, but it is nothing more than considering several aspects such as technological progress, cost reduction, shortening of supply cycle, improvement of quality control level, development scale and speed, etc. , make progress together. What procurement needs is preferably professional knowledge, certain negotiation experience and skills, and a certain understanding of the market. The senior management and managers of both buyers and sellers will meet every quarter to resolve the negative phenomena that existed in the early stage and propose future development. Goals and strategic goals allow suppliers to have a clear idea and fully cooperate with our company's development process.

9,

How to maintain the old supplier relationship?

Answer: Maintenance of supplier relationship: Because the supplier is not a customer, there is no need to take the initiative to call to maintain emotional contact. Contact only when necessary. Generally, suppliers will take the initiative to call For procurement, business matters, if it is a private matter, just treat it like an ordinary friend!

10,

How to determine the authenticity of the supplier's quotation?

Answer: Through price comparison with multiple companies; through cost analysis; through the functional positioning of the product. Compare with equivalent products to determine.

11,

The old supplier quotes slightly higher than the new supplier every time, but after communication, they agree to lower it appropriately. How should this situation be handled?

Answer: Ship the goods separately and purchase in small batches from the new supplier. Of course, most of this batch will come from old suppliers. Because a product is not only about price, but also about specifications, appearance, service life, delivery time, etc. I have to make a final decision after testing in small batches. In addition, generally speaking, the company's share of the same product should be 37, and whoever has the advantage will get the lion's share. Various situations will arise in actual production, and only two suppliers can effectively solve these problems.

If in the end the price of the old supplier is higher than the new one, then I will buy the bulk from the new one, but I will still maintain the supply and demand relationship with the old supplier. A long-term supplier is a wealth. If the price is the same, I will buy the bulk from the old supplier and retain the supply qualification of the new supplier.

12,

How to reasonably reduce procurement costs?

Answer: Make a reasonable procurement plan in advance, check the current market conditions, and understand the factors and events that affect costs. During the process, look for quotes from multiple qualified manufacturers, make a base price or budget, and use negotiation skills. Afterwards, choose a manufacturer with an appropriate price to sign a contract and use quantity or cash discount .

13,

What is the cost composition of purchased goods?

Answer: Engineering or manufacturing methods, required special tools and equipment, direct and indirect material costs, direct and indirect labor costs, manufacturing overhead or outsourcing expenses, marketing expenses and taxes, and profits .

14,

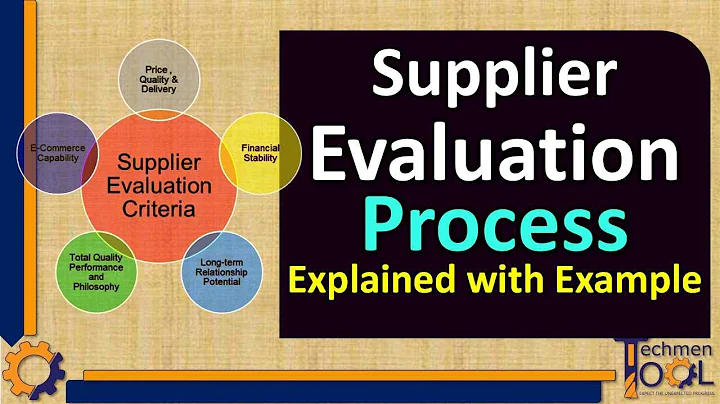

How to analyze suppliers?

Answer: Price, quality, service, location, inventory policy, flexibility.

15,

When purchasing encounters delivery delays and shortage of materials, how to take emergency remedial measures to reduce losses?

Answer: Require supplier materials (transfer or borrow order inventory from other factories); ask other manufacturing peers or related companies (peers) ) Borrow materials; log in to electronic materials related websites to search for inventory or substitutes; ask the engineering unit to help find substitutes or change circuits and specifications based on material characteristics and specifications; request production management in advance for the production schedule to avoid line interruption losses; Based on material characteristics and specifications, search for inventory materials with similar specifications, substitute products, or change circuits and specifications.

is compiled from the Internet. It is only for learning and communication. If there is any infringement, please contact us to delete