1, meaning

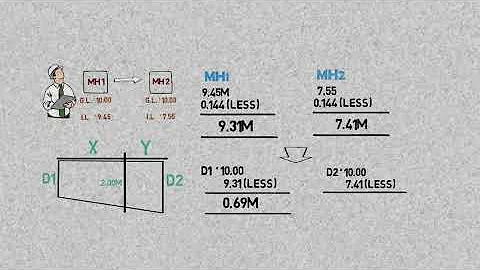

(1) Tunnel side ditch refers to longitudinal drainage ditches set up on both sides of the tunnel road surface. The side ditches on the roadside can be set up as open ditches or hidden ditches. Sand settling tanks and water filter grates should be installed. The spacing should be 25-30m.

Tunnel side ditches are mainly used to collect groundwater and at the same time play the role of sedimentation and solid drainage. side ditch trenches are made of C25 reinforced concrete, and the cover plates are made of C35 reinforced concrete.

(2) Tunnel center drainage trench usually uses precast concrete pipes, the backfill material uses graded gravel, and the cover plate is poured with C25 concrete.

The central ditch section should be rectangular, and desilting tanks should be set at intervals of 50-200m.

(3) Sand settling wells and inspection wells, Side ditch sand settling wells are arranged in full tunnels, with a longitudinal spacing of 50m; center drainage ditch inspection well spacing is 25m

2. It is required that

tunnel concrete trenches be constructed in sections , divided The construction section should not be too short and the line must be straight. Deformation joints should be set every 30m. The formwork should be combined steel formwork . The trench cover should be prefabricated in a factory and transported to the site.

3, quota application analysis

(1) Concrete trenches are prepared according to cast-in-place, prefabricated and cover plates and steel bars

(2) Prefabricated trenches and cover plates comprehensively consider the transportation of prefabricated blocks, mortar masonry, etc. But it does not include mixing

(3) inspection wells , sand wells, concrete drainage pipes and other related quotas. It is recommended that be applied to the subgrade drainage project. Don't forget to adjust the manual and mechanical correlation coefficients.

[Original article! Be sure to apply for authorization when reprinting, and indicate the author and source. This article only represents my personal views and is for reference only. Please correct me if there is any inaccuracy]

The tunnel project of actual highway project cost construction has started, welcome to join!

If it is helpful to you, welcome to "like, collect, repost, follow"

will continue to provide you with original pricing information