FPC is the abbreviation of Flexible Printed Circuit, also known as flexible circuit board, flexible printed circuit board, flexible circuit return, referred to as soft board or FPC. It has the characteristics of high wiring density, light weight and thin thickness. Mainly used in mobile phones, laptops, PDA, digital cameras, LCM and many other products. FPC flexible printed circuit is a highly reliable and excellent flexible printed circuit made of polyimide or polyester film as the base material.

FPC flexible circuit board is characterized by being light, thin and short, so it is also the best choice for most smart electronic products. flexible circuit board is also easy to produce punches, folds, scars and other operations during use. It has low mechanical strength and is prone to cracks. crack. Therefore, the purpose of laminating reinforcing materials is to enhance the mechanical strength of the FPC flexible circuit board and facilitate the installation of parts on the PCB surface. There are many types of reinforcing films used in flexible circuit boards, depending on the use requirements of the product. The main ones are PET , PI, adhesive , metal or resin reinforcing plates, etc.

Today we will explain to you the flat knife die-cutting process of FPC with holes and adhesive:

Material matching:

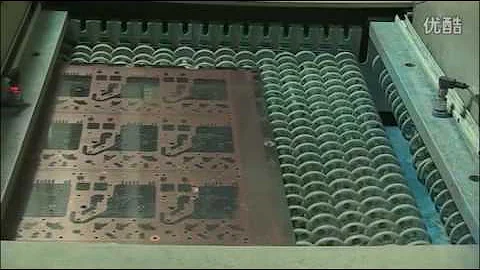

Detailed process steps and machine diagram

The FPC with holes and adhesive process is divided into five steps, namely laminating a Punching, laminating, two punching, laminating and rewinding, the equipment required are: HW-T300-3 three-station laminating machine -D200 small hole high-speed nesting die-cutting machine-HW- T300-3 three-station laminating machine - D200 small hole high-speed nesting die-cutting machine - HW-T300-3 three-station laminating machine.

1. Laminating steps

1. First, cover the non-release surface of the 0.075 blue release film with 0.05 acrylic protective film 2. Then center the black tape adhesive surface on the release surface of the 0.075 blue release film

2 , Precautions for punching and punching

The knife die punches the black glue on the paper surface, all holes are completely cut off, the handle one-line knife only punches through the black glue, blue film cannot punch through

3. Laminating steps

1 , on the laminating machine, remove the waste

2 in the middle of the handle line knife product, then roll up the conductive cloth surface layer with its own release paper

3, and cover it with 0.065 white glassine paper.

Precautions for 4th and 2nd punch cutting

The knife die is punched to the 0.075 blue release film surface, and the bottom 0.065 white glassine paper cannot be punched

5. Laminating steps

Remove the product outer frame waste on the laminating machine, and collect the finished product volume