Source: "China Petroleum and Chemical Industry Observation" magazine

Translator: Zhang Xing

Energy researchers at the University of Minnesota-Twin Cities recently developed a device called a catalytic condenser. It can be used as a catalyst to speed up chemical reactions by making one metal behave like another through electronic modification of the metal's surface. The device is the first to demonstrate that electronically modifying alternative materials with new properties can enable chemical reactions to proceed faster and more efficiently.

The invention paves the way for non- precious metal catalysts to replace precious metal catalysts for important chemical reactions, such as storing renewable energy, making renewable fuels and creating sustainable materials.

The research results were published on the website of JACS Au, a sister publication of the Journal of the American Chemical Society, on May 7. The research team holds a provisional patent for the device and is working with the University of Minnesota's Office of Technology Commercialization.

In the last century, difficult chemical reactions have always relied on the use of some precious metal materials as chemical reaction catalysts to improve reaction efficiency and product yield. These include precious metals such as ruthenium, platinum, rhodium and palladium. These metals have unique electronic surface properties that are critical for controlling chemical reaction rates and product yields.

But these metals are very expensive. For example, car catalytic converters are often stolen because they contain rhodium and palladium. In fact, palladium may be more expensive than gold.

Across the world, these expensive materials are in short supply and have become a major obstacle to the advancement of chemical synthesis technology.

Researchers from the team relied on their understanding of how electrons behave on metal surfaces to successfully test a theory that adding and removing electrons from one material can allow one metal oxide to mimic the properties of another material , so catalyst materials with the same catalytic function as precious metals can be obtained in a relatively cheap way.

" atoms actually don't want to change the number of electrons on their own, but the catalytic condenser device we invented can adjust the number of electrons on the surface of the catalyst." said Paul Dauenhauer, a MacArthur Fellow and professor of chemical engineering and materials science at the University of Minnesota. , "This provides a completely new opportunity to control chemical reactions and enable more materials to play the role of noble materials."

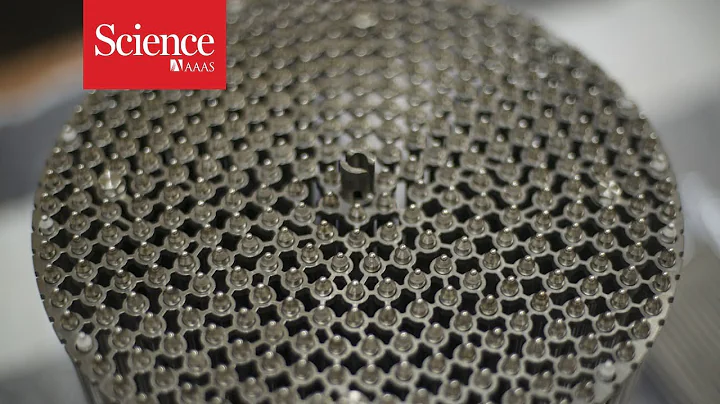

This catalytic condenser uses a combination of nanofilms to move and stabilize electrons on the surface of the catalyst. This design features a unique mechanism that combines metals and metal oxides with graphene to enable fast electron flow.

"Using a variety of thin film technologies, we combined a nanoscale aluminum oxide film made from the low-cost and abundant aluminum metal with graphene and then tuned it to have the properties of the precious metal material." said a postdoctoral researcher at the University of Minnesota who was involved in the development of the technology.

As a platform device, the catalytic condenser design has a wide range of practicality. This versatility comes from its nanofabrication technology. The technology uses graphene as an active ingredient in the active surface layer, and its ability to stabilize electrons can be tuned through different compositions of the strongly insulating inner layer.

The active layer of the device can also combine any base catalyst material with other additives, which can then be tuned to achieve the catalytic performance of noble metal catalytic materials.

"Catalytic condensers are a platform technology that enables the fabrication of many new materials," said Dan Frisby, chair of the Department of Chemical Engineering and Materials Science at the University of Minnesota and a member of the research team. "The combination of core designs and innovations can be applied to our Almost any chemical composition imaginable. "

The team stated that they will continue to promote the research of catalytic condenser , apply it to a wider range of fields, and reduce the application cost of efficient catalytic technology to solve some important chemical industries. Sustainable development and environmental protection issues.

With financial support from the U.S. Department of Energy and the National Science Foundation, several projects utilizing this catalytic condenser technology are already underway, such as storing renewable electricity as ammonia, a key ingredient in the synthesis of renewable plastics. , and treat various polluting waste gases.