KROM natural gas pressure switch is when the pressure in the system is higher or lower than the rated safety pressure, the disc in the sensor moves instantaneously, and the switch joint is turned on or off by connecting the guide rod. When the pressure drops or rises to the rated safety pressure, When restoring the value, the disc is instantly reset. pressure switch , as the name suggests, measures gas or air pressure in real time and outputs a switch signal to the system when the pressure exceeds the high limit or low limit, so that the system can process it accordingly.

KROM Hocod Pressure Switch

A small pressure switch that seems to have a simple structure, but in fact it has many functions that everyone does not know or often ignore. Let’s take a look at the introduction given by the editor of Lihebo below. The working principle of the

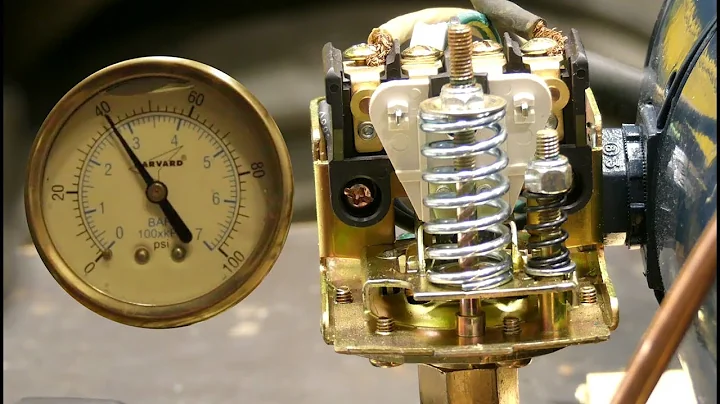

pressure switch is: when the pressure in the system is higher or lower than the rated safety pressure, the disc in the sensor moves instantaneously, and the switch joint is turned on or off by connecting the guide rod. When the pressure drops to or When the rated recovery value is increased, the disc instantly resets and the switch automatically resets. Or simply put, when the measured pressure exceeds the rated value, the free end of the elastic element is displaced, pushing the switching element directly or after comparison, and changing the switching element. On-off state to achieve the purpose of controlling the measured pressure. The elastic components used in pressure switches include single-turn spring tubes, diaphragms, diaphragm boxes, bellows , etc.

Knowledge point 1:

Pressure switches essentially do not distinguish between high pressure and low pressure

Generally, we are required to install two pressure switches on the gas main line, called high pressure switch and low pressure switch , to form high and low pressure protection of gas pressure. A pressure switch will also be installed on the combustion air duct to serve as an under-pressure alarm.

In fact, for the pressure switch, there is no distinction between high and low, only the measuring range is different. Generally, we call the one with a small range used for low-voltage alarm (or low-pressure cut-off) a low-voltage switch, and the one with a large range used for high-voltage alarm (or high-pressure cut-off) called a high-voltage switch.

But this level is not absolute, but relative. The same pressure switch can be used as either a high-pressure switch or a low-pressure switch under different operating conditions.

Knowledge point 2:

The pressure switch can also measure negative pressure and differential pressure

Different brands of pressure switches have slightly different structures and functions, but the pressure switches of mainstream brands on the market can measure positive pressure, negative pressure and differential pressure at the same time. pressure.

For example: when measuring the positive pressure of and , you only need to connect 1 or 2; if you want to measure negative pressure, connect 3 or 4. Then to measure the differential pressure, connect 1 and 3 (or 2 and 4).

Knowledge point 3:

When the high and low voltage switches are used for safety interlocking, the wiring is reversed.

The safety interlocking mentioned here refers to the hard interlocking directly connected in series to the power supply line of the main cut-off valve. That is, when the gas pressure is ultra-low or ultra-high, the gas supply is directly cut off to protect the combustion system.

Each pressure switch has a set of contacts, NO represents normally open, NC represents normally closed, and COM represents the common terminal.

When there is no ventilation in the pipeline, whether it is a switch for low pressure or high pressure, their contacts do not change. However, once the pipeline is ventilated, under normal operating pressure, the low-pressure switch contacts have changed, normally open to close and normally closed to open.

Therefore, the cut-off valve circuit must be connected in series to the two pressure switches. The correct answer should be: the low-pressure switch is connected to the normally open contact, and the high-pressure switch is connected to the normally closed contact.

Knowledge point 4:

Two pressure switches can be bound together for installation

The general installation method is to lead two thin tubes from the pipeline, and then install the low-pressure switch and the high-pressure switch respectively. Of course this is understandable, but it takes up a lot of space. In places where the installation space is limited, the following connection method is the right way.

Specific to the connection of the pressure switch itself, the method is as follows: remove the plugs on the positive pressure interfaces (port 2) on the sides of the two switches, connect the two interfaces so that the two positive pressure chambers are connected, and then block them The positive pressure interface of one switch (port 1) only connects the positive pressure interface of the other switch to the pipeline. The elastic components used in pressure switches include single-turn spring tubes, diaphragms, bellows, etc. Gas pressure switches are used in various industrial uses and heating systems allowed by industrial gas, and are used for gas, air, flue gas and other media.