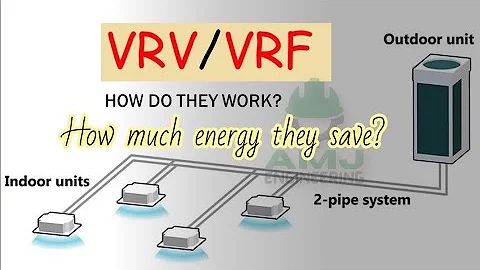

The variable frequency multi-split system is the abbreviation of "variable frequency one-to-one variable refrigerant flow central air conditioning system". It is a refrigerant circulation system composed of one outdoor unit and several indoor units. It uses refrigerant as the transport medium, and can meet indoor cooling and heating load requirements in a timely manner by controlling the refrigerant circulation volume of compressor and the refrigerant flow rate entering each indoor unit.

1. Composition of variable frequency multi-connection system

Outdoor unit: From a structural point of view, it is mainly composed of an outdoor heat exchanger, a compressor, an electronic expansion valve and other accessories. When the system is at low load, the frequency conversion controller controls the compressor speed to change the circulation flow of the refrigerant in the system, thereby automatically controlling the cooling capacity to meet usage requirements. For units with a smaller capacity, there is usually only one variable-speed compressor; for units with a larger capacity, a variable-speed compressor and one or more fixed-speed compressors are generally used to work together.

Indoor unit: It is a device with an evaporator and a circulating fan. It is in principle the same as the indoor unit of the split air conditioner that we commonly see at present. From a formal point of view, in order to meet the requirements of various buildings, it is made into various forms, mainly including floor-standing machines, wall-mounted machines, duct machines, embedded machines, etc. These indoor units can be freely combined according to actual needs.

Duct air conditioner: Duct air conditioner is commonly known as air duct machine. The air conditioner is connected to the air duct to supply air to the room. Duct air conditioners solve the problem of hanging or cabinet units being exposed to the outside, which affects the appearance. At the same time, the length of the duct is longer than that of ordinary household air conditioners, and the installation is more flexible. According to static pressure, there are three forms: high and low static pressure. Embedded machine: It has a beautiful and generous appearance, and has good cooling and heating effects. Common ones include four-sided air outlet built-in, double-sided air outlet built-in, and single-sided air outlet built-in. 2. Frequency conversion multi-online system composition

Refrigerant tube: Refrigerant tube generally uses copper tube. It consists of air pipes and liquid pipes, and connects the outdoor unit to the indoor unit through flexible arrangement. Refrigerant pipes need to be insulated.

Branch pipe: It shunts the refrigerant in the pipe to each indoor unit to play a diversion role. Before installation, you need to check whether the diameter of the copper pipe is consistent with the diameter of the required branch pipe. If the size of the copper pipe at the installation site is different from the diameter of the required branch pipe, use a cutter to cut off the different parts.

Condensate water pipe: The evaporator of refrigeration equipment will produce condensation water during the refrigeration process. condensate water pipes generally use PVC plastic pipes, and the condensate water pipes need to be insulated. Duct: Duct is a system of pipes used for air transport and distribution. According to the cross-sectional shape, air ducts can be divided into round air ducts, rectangular air ducts, oblate air ducts, etc. According to material, air ducts can be divided into metal air ducts , composite air ducts , and polymer air ducts. Air outlet: It is used for air supply and return air in the air conditioning system. The air supply port sends the cooled or heated air to the room, and the return air port sucks back the indoor dirty air. The two form an entire air circulation system.

Common air supply outlets include double-layer louver air outlet , diffuser , spherical adjustable air outlet, swirl air outlet , etc. Common return air vents include single-layer louver air vent , etc. Common air outlet materials include aluminum alloy, plastic, carbon steel, wood, etc.

Refrigerants: Commonly used refrigerants in air conditioning projects include R22, R410a, etc. R410a does not destroy the ozone layer, its working pressure is about 1.6 times that of ordinary R22 air conditioners, and its cooling and heating efficiency is higher. R410a is an internationally recognized refrigerant that is suitable to replace R22.

The method for calculating the refrigerant addition amount of multi-split air conditioning pipelines is: (the calculation method is different for each brand) The total length of the liquid pipe with a pipe diameter of 15.88mm × 0.17 + the total length of the liquid pipe with a pipe diameter of 12.7mm × 0.11 + the pipe diameter is 9.53mm The total length of the liquid pipe × 0.057 + the total length of the liquid pipe with a diameter of 6.35mm × 0.022 Control system: The control system mainly has the following forms: wireless remote control, wired remote control, centralized controller, network management system, etc.

2. Installation precautions and scope of application

The outdoor unit can be placed directly on the roof, balcony or open space outside the building. There is no need to set up a machine room, and there is no need for cooling towers , water pumps, softened water and other cumbersome ancillary equipment, saving a lot of construction. area and infrastructure investment. However, when installing the outdoor unit, attention must be paid to ventilation issues to avoid short circuiting the air flow and affecting the cooling and heating effects.

The appearance and dimensions of the indoor unit are very compact. The connected refrigerant pipe is very thin and there is no slope requirement for installation. The indoor unit itself is equipped with a condensate water lifting pump, which can increase the installation height of the condensate water pipe. If a suspended ceiling is required, it can greatly save the ceiling space. When installing the indoor unit, wrap it to prevent dust and impurities from entering the indoor unit. During the welding process of the refrigerant pipe, nitrogen must be filled into the pipe (nitrogen shielded welding). This leaves no air inside the copper pipe and avoids carbon formation on the inner wall during welding, which may enter the compressor during official operation and cause failure. Before filling the refrigerant pipe, the refrigerant pipe needs to be evacuated to take out the air in the pipe and keep it dry and moisture-free. Otherwise, the air and water will mix with the refrigerant to produce ice crystals, which may seriously damage the equipment.

When installing the condensate pipe, you need to pay attention to water leakage. Frequency conversion multi-connection system can be widely used in various buildings: ① those with weak management capabilities, such as hospitals, schools, etc.; ② those with low room utilization, such as resorts, villas, etc.; ③ those with room and household charges and centralized management, such as Rental of office buildings, office buildings, commercial and residential buildings, etc.; ④ Small and medium-sized projects, such as corporate office buildings, hotels, etc.; ⑤ Large load fluctuations and different use functions, such as large shopping malls, gymnasiums, etc.