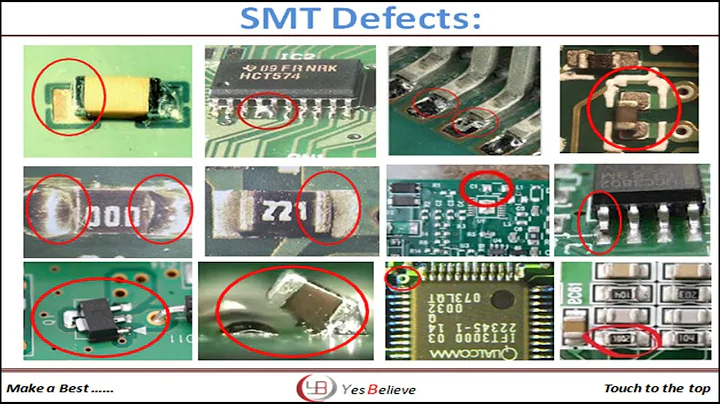

Many manufacturing defects often occur during SMT processing, which will directly affect our production quality. Below, Lingzhuo PCBA manufacturer will talk about several common production defects and solutions in SMT processing.

1. Wicking phenomenon

Also known as material sucking phenomenon, also known as core-pulling phenomenon, it is one of the common welding defects, and is more common in vapor phase reflow soldering. This defect is that the solder breaks away from the pad and travels up the pin to between the pin and the chip body, causing a serious virtual soldering phenomenon. The usual reason is that the thermal conductivity of the pin is too large and the temperature rises rapidly, so that the solder wets the pin first, and the wetting force between the solder and the pin is much greater than the wetting force between the solder and the pad, causing the pin to rise. Replacing the update will aggravate the occurrence of wicking.

The solution is:

First, fully preheat the SMA and then solder it in a furnace. Carefully check and ensure the solderability of the PCB pad. The coplanarity of the components cannot be ignored. For devices with poor coplanarity, Not to be used in production.

2. Unmelted

There are two adverse phenomena of unmelted:

① If unmelted occurs in a fixed place, inspect according to Table 5;

② If the place of occurrence is not fixed and it occurs immediately, inspect according to Table 3.

When an unmelted defect occurs, the items to be inspected

1. Is the unmelted component a component with a large heat capacity?

2. Is a component with a large heat capacity mounted on the back side of the substrate, forming a thermal conductivity obstacle?

3. Occurrence Are there components with large heat capacity around the unmelted components?

. 4. Are there any unmelted components assembled at the end of the substrate?

. 5. Are there any thermal capacitances such as the substrate ground wire or power line in the unmelted area? Large parts are connected;

6. Is the unmelted place a hidden part, that is, a structural state that is difficult to directly contact with hot air or infrared rays?

3. Chip component cracking

Cause:

① For MLCC type capacitors, there is great fragility in its structure. Usually MLCC is made up of multi-layer ceramic capacitors , which has low strength and is extremely fragile. Intolerant to thermal and mechanical shock. Especially in wave soldering ;

② During the placement process, the pick-up and release height of the Z-axis of the placement machine, especially for some placement machines that do not have the Z-axis soft landing function, the pick-up and release height is determined by the chip type The thickness of the component is not determined by the pressure sensor , so the tolerance of the component thickness will cause cracking;

③ PCB flexural stress, especially after welding, deflection stress can easily cause cracking of the component;

④ Some spelling When the PCB of the board is divided, the components will be damaged.

Preventive measures are: Carefully adjust the welding process curve, especially the temperature in the preheating zone should not be too low; Carefully adjust the pick-up and release height of the Z-axis of the placement machine; Pay attention to the shape of the panel cutter; The deflection of the PCB , especially the deflection after welding, should be corrected in a targeted manner. If it is a PCB board quality problem, special consideration needs to be given.

If you want to know more about common defects and solutions in the SMT processing process, you can follow Lingzhuo PCBA. If you need to know more technical knowledge about PCB proofing, SMT patching, and PCBA processing, please leave a message to get it. !