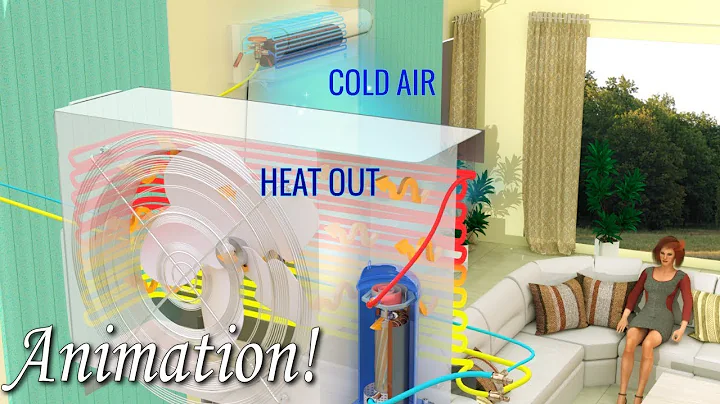

Industrial air conditioners refer to air conditioning equipment that provides ambient temperature, humidity, and cleanliness guarantees for the production process of industrial products or the reliable operation of industrial process equipment. Such as the constant temperature and humidity air conditioner used to ensure the normal operation of the equipment in the electrical control room, the high-temperature environment special air conditioner used in the mobile bridge crane in the steelmaking workshop, and the low-temperature unit air conditioner used in the meat processing workshop. etc., all belong to industrial air conditioners. So what are the different characteristics of industrial central air conditioners? How to clean and maintain industrial central air conditioners? Let’s find out together.

Zhongtong intelligent combined air conditioner

1. Characteristic analysis

Industrial central air conditioners need to be managed and operated by dedicated personnel during daily use. In terms of settings, try to use the cooling state to keep the air clean. Do not frequently switch the working state of the environmentally friendly air conditioner during use.

Industrial central air conditioners generally have relatively large power and high power consumption. The operation design must ensure that the equipment can run for a long time. When choosing industrial central air conditioners, you also need to pay attention to the quality of the parts and components. Try to choose brand products with good quality and guaranteed quality. The price may be slightly higher, but after a long time of use, the price/performance ratio is still very high. Industrial central air conditioners treated with baking paint have good anti-corrosion properties, are strong and durable, and play a huge role in industrial production.

Zhongtong intelligent constant temperature and humidity machine

2. Cleaning and maintenance methods of industrial central air conditioners

1 Physical cleaning of industrial central air conditioners

Commonly used physical cleaning methods include main engine blasting, that is, through compressed air or manual use of punches, rubber plugs, nylon brushes or round steel and other tools pass through the heat exchanger tube to remove accumulation or blockage in the tube. Open the end cover of the main engine, use a gun passer to pass the copper pipes one by one, clean the biological slime and rust residue on the pipe wall, and rinse with high-pressure water after the pass. Then thoroughly eradicate all rust residue and scale on the side of the water chamber and the inner wall of the end cover, and apply anti-rust paint twice to play the role of rust removal, rust prevention, scale removal, and scale prevention.

2 Industrial central air conditioning chemical cleaning

is a type of cleaning method that uses the action of chemicals to dissolve, loosen, fall off or peel off the deposits in the equipment being cleaned. Commonly used chemical cleaning methods include pickling, alkali cleaning, complexing agent cleaning, sterilization cleaning, etc. Chemical cleaning is generally used to remove hard scale in equipment and pipelines and deposits in bends and joints. Adopting a professional single-machine cycle cleaning method, using organic acid plus complexing agent, coupled with high-efficiency corrosion inhibitors, the corrosion of copper pipes is more than ten times lower than that of inorganic acid , and it can be quickly removed on the basis of effectively protecting the equipment. Dirt and rust removal. Pre-filming the copper pipes after cleaning can greatly slow down the corrosion rate of the equipment.

Zhongtong intelligent stainless steel air duct machine

3 Industrial central air conditioning maintenance method

Open the suction grille, hold the two buttons, and slowly pull it down at the same time, drag the hook on the air filter and pull it out diagonally downwards, and take it out Filter, cleaning method: Use vacuum cleaner to remove dust, or clean it with clean or warm water. If there is too much dust, use a soft brush and neutral detergent. After cleaning, shake off the water, and then put it in a cool place to dry. Remember not to wash with hot water above 50℃ to avoid discoloration or deformation; do not dry it over a fire, as the filter may catch fire. Be sure to install the air filter after cleaning. Hang the air filter on the protruding part on the upper part of the suction grille, and then fix it on the suction grille; slide the convex handle on the back of the suction grille inward, install the air filter on the suction grille, and close the suction grille. Contrary to step 1, press the filter signal reset button on the control panel, and the central air conditioning cleaning reminder sign will disappear.If there is too much dust in the use environment, the air filter should be cleaned about once every six months.

Zhongtong intelligent unit air-cooling unit

Part of the content comes from the Internet,

If there is any infringement, please contact the background to delete