In recent years, as the aging of the population continues to intensify, my country's demographic dividend advantage is disappearing. Judging from the rapid development and structural layout of the industry, rising labor costs have led to a shortage of workers in the manufacturing industry, making recruitment difficult and expensive. How should manufacturing companies carry out industrial upgrading? How to improve the automation level of the production line to reduce costs and increase efficiency? These questions have become must-answer questions for enterprises on the road to high-quality development of and .

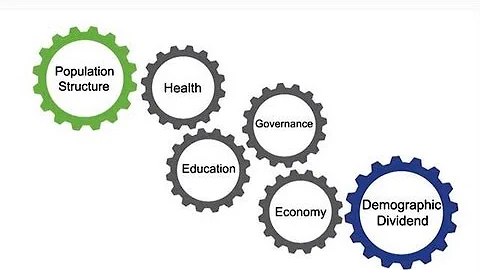

The transformation and upgrading of the manufacturing industry is inseparable from the intelligent and digital development of enterprises, which is also an important way to achieve my country's "manufacturing power". As one of the core technologies of intelligent manufacturing system , machine vision technology makes the production process visual and intelligent through visual perception, transmission calculation, etc., which not only improves production efficiency and product quality, but also frees manpower from heavy, monotonous, and The liberation of dangerous labor has injected new momentum into the development of the industry.

Nanjing Nanxuan Heya Technology Co., Ltd. (hereinafter referred to as "Nanxuan Heya") focuses on the research and development and application of machine vision products, using technological innovation to empower manufacturing companies, using artificial intelligence , machine vision and other technological means to... Fundamentally solve the employment problem of welding enterprises. At present, Nanxuan Heya products have been widely used in shipbuilding, new energy batteries, automobile manufacturing, electronics manufacturing and other industries, promoting the intelligent transformation of manufacturing enterprises.

Nanxuan Heya machine vision product application fields

Free your hands and realize unmanned welding scenes

Machine vision is one of the artificial intelligence technologies most closely related to the industrial manufacturing field. According to the "2022 China Industrial Vision Market Research Report" released by Jiazi Guangnian, between 2016 and 2021, the scale of my country's industrial vision market increased from 4.7 billion yuan to 17.8 billion yuan. Under the "two-wheel drive" of policy and market , is expected to successfully break through the 50 billion mark in 2026, and the annual compound growth rate will remain at around 25%.

Welding work is known as "industrial tailoring". It is an important processing method in industrial production and a key link in intelligent manufacturing technology. For welding enterprises, due to the special nature of the industry, a large amount of smoke, dust, and metal welding flowers will be produced during the welding process. The working environment is very harsh, low production capacity, and labor difficulties have become pain points for the development of welding enterprises.

"My father's generation, the generation born in the 50s and 60s, many are front-line operators. I have seen them with my own eyes repeating simple mechanical work in harsh front-line environments. I think, like welders, lathes, and electricians These types of work should gradually disappear with the continuous development of technology. "In the view of Jiang Qi, founder and CEO of Nanxuan Heya, machine vision technology should be used in manufacturing welding processes and replaced by more refined welding robots. It is the original intention of Nanxuan Heya to use artificial labor to achieve the goal of freeing hands and accelerating the intelligent transformation of manufacturing enterprises.

Nanxuan Heya single-station intelligent automatic welding workstation

Data shows that my country’s industrial robot sales have increased from less than 25,000 units in 2012 to more than 248,000 units in 2021. Market sales in 2022 are expected to reach 300,000 units. Among them, welding robots account for more than 40% of the total industrial robots.

Jiang Qi told 6氪 that in robot welding scenarios, it is not enough to separate people from "operators" to "decision makers". Positioning people as "observers" is the ultimate goal of intelligent transformation. . "Where to weld, how to weld, how to move the robotic arm, how to adjust the posture and process...this series of issues do not require human participation in decision-making. This is the true intelligence of manufacturing."

human-machine "link" inspires Compared with manual welding operations, manufacturing enterprise productivity

, with the support of machine vision technology, welding operations have become smarter, more precise and reliable, have better environmental adaptability, and higher production efficiency. Therefore, in modern industrial production and intelligent manufacturing are playing an active role in other fields.

However, most of the current visual robot automatic welding solutions on the market are intelligent "teaching pendants". The welding process requires full human participation, whether it is the basic model of welding, specific parameter settings, or detailed weld information, etc. All require the operator to participate in decision-making.For enterprises, such a workflow requires a lot of time to train workers in the early stage. In the actual operation process, once the data of the welding robot is even slightly different from the preset, the workpiece will be scrapped.

In the production workshop of Jiangsu Runyang Robot Co., Ltd., the single-station intelligent automatic welding workstation provided by Nanxuan Heya is operating at full capacity. In the huge workshop, only individual operators shuttle between workstations. The operator only needs to import the three-dimensional model of the workpiece in advance, determine the welding process, and place the workpiece on the welding platform . The welding robot can automatically scan the workpiece for welding operations through machine vision technology.

Actual pictures of Nanxuan Heya product operations

Apply machine vision technology in the field of intelligent automatic welding. The single-station intelligent automatic welding workstation produced by Nanxuan Heya has once again changed the ecology of the field of welding operations: SmartWelder intelligent visual welding software transparency Through the visual adjustment interface, which integrates 2D+3D vision, deep learning, artificial intelligence and other technologies, you only need to collect data from the original drawings of the workpiece to automatically build a three-dimensional model; with the welding construction equipment, the task of feeding and welding is a matter of course. With the data collected by the software for comparison, the error of automatic welding is reduced to a minimum, thus ensuring the welding quality. At the same time, without direct manual participation, the risk factor during the welding process is also reduced to a minimum.

"The ultimate design goal of our products is to replace welders, not to make welding simpler." Jiang Qi said that the single-station intelligent automatic welding workstation developed by Nanxuan Heya is easy to operate, easy to train and manage, and can be used with different welding robots. , and the workstation can automatically identify and position, and perform welding work on different types of workpieces such as structural parts, purlin pallets, assembly parts, H-shaped steel beams, tube sheets, steel bars, sheet metal carbon steel, etc. "The workstation has good adaptability and stability, and can help companies reduce more than 70% of welding labor costs and improve production efficiency."

deeply explores vertical fields and promotes the intelligent transformation of manufacturing industry

The transformation and upgrading of manufacturing industry is a system And long-term tasks, judging from the implementation of the welding intelligent workstation developed by Nanxuan Heya and the development prospects of product technology, the application scope of intelligent visual welding in manufacturing enterprises is constantly expanding.

Nanxuan Heya has 12 nationally authorized invention patents and 13 software patents

At present, Nanxuan Heya has reached cooperation with leading enterprises such as a large domestic shipbuilding group, and intelligent automatic welding workstations have also been successfully put into production. At the same time, Nanxuan Heya is also actively deploying and implementing single-station vision-guided welding products for small and medium-sized enterprises, and has reached strategic cooperation with leading domestic robot manufacturers and well-known universities such as Nanjing University of Science and Technology , China Southern Airlines , Nanjing University of Technology and other well-known universities. In the future, Nanxuan Heya will continue to delve into the field of intelligent visual perception, improve its independent innovation capabilities, promote product iterations and brand upgrades, launch new products covering multiple scenarios, and assist manufacturing enterprises in transforming and upgrading to intelligence and digitalization.

"With the development of Nanxuan Heya, products and solutions are used in the production and manufacturing of heavy equipment in major countries. Some products can even fill the market gap where foreign high-end models are prohibited from being sold in China. We are sincerely gratified and proud, and even more He is determined to continue working on the machine vision track. "

Do you want to become a future unicorn?" 36Kr Jiangsu can help you!

If you want to self-recommend excellent entrepreneurial projects and seek special reports on companies/activities; if you want to release initial financing information; if you want to provide original articles or videos for 36 Krypton, reprint 36 Krypton Jiangsu original articles or communicate with other content-related cooperation … Please add 36kr Jiangsu WeChat account jiangsu-36kr, or send your needs and projects BP to [email protected], we will contact you in time.

For business cooperation, please contact Mr. Ji directly Tel: 18101595688, WeChat ID: amiman.