Many customers will have this idea: The thicker I apply waterproof coating , the faster and better the waterproofing effect will be. So is this true?

Lumen waterproof and anti-corrosion: The waterproof years are indeed closely related to the thickness of the waterproof layer. We know that the waterproof coating layer is continuous and impermeable. Even if it is 0.5mm, it can be effectively waterproof, but such a thin coating can easily be Mechanical damage cannot withstand a certain amount of displacement. Generally speaking, first-level waterproofing (20 years of service life), the waterproof coating film is not less than 2.0mm, and second-level waterproofing (10 years of service life), the waterproof coating film is not less than 1.5 mm. But this does not mean that the thicker the waterproof coating, the better. On the one hand, it is not economical, and on the other hand, too much thickness can easily lead to cracking.

The correct construction of LM composite waterproof coating is as follows:

1. Base layer treatment

The base layer requires smoothness, compacted and calendered surface, no sharp edges, no honeycomb pitted surface , and no bulging cracks, otherwise it must be treated to the above Ask for it. Construction waste and floating ash on the surface of

must be removed. There should be no open water on the base layer of

, otherwise it should be removed and cleaned.

2. Detailed node processing

The pipe roots, pipes, yin and yang angles, construction joints and other parts prone to water leakage should be treated with force, and then apply the waterproof coating one to two times with a brush

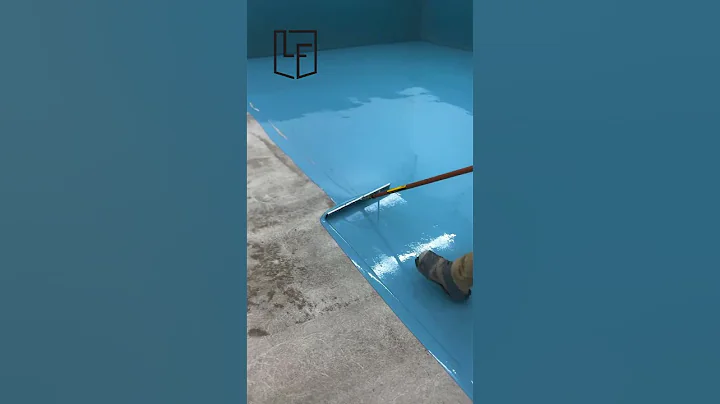

3. Application of LM composite waterproof coating After the detailed nodes of

are processed and the coating is dry, the large-area coating is applied. The construction can be carried out by roller coating, brush coating, scraping coating, etc. The construction should be uniform without local deposition, and should be applied multiple times to ensure that no air bubbles are left between the paint and the base layer. After the first coat of coating dries (generally an interval of 6-8 hours is appropriate, the specific detection method is based on non-stick finger prints), apply the second coat of coating in a direction perpendicular to the first coat. The construction should be uniform and there should be no local sedimentation. After the second coat of paint is dry, apply the third coat of paint. The third coat of coating is rolled with a long-handled roller. The direction of the rolling coating is perpendicular to the second coat of coating. The rolling coating should be even and there should be no local deposition to improve the flatness and smoothness of the coating surface. The coating film should be closed. Waterproof paint should be applied multiple times to ensure complete waterproofing effect.

The coating film should be completely dry for 2 days before the next construction process can be carried out. During construction, attention should be paid to the protection of the waterproof layer of the coating film to avoid artificial or external damage to the waterproof layer.

Lumen waterproof and anti-corrosion: So the more layers of waterproof coating, the better!