Wuhan University Chen Shengli & Luo Wei JACS: Surface oxygen embedded nickel-based nanocatalysts for efficient alkaline hydrogen oxidation

First author: Men Yana, Su Xiaozhi, Li Peng

Corresponding author: Professor Chen Shengli, Professor Luo Wei

Corresponding unit : School of Chemistry and Molecular Science, Wuhan University

Paper DOI: https://doi.org/10.1021/jacs.2c01448

Full text Quick view

Design of synergistic optimization of nickel metal through the strategy of oxygen embedding in the nickel surface layer The reaction that interacts with OH species The bond orbital filling degree (ABF) and the energy level matching degree (ELA) between the two can realize the directional regulation of the OH binding energy (OHBE) by reducing the antibonding orbital filling degree and increasing the energy level matching degree. DFT calculation and experimental results show that as the surface oxygen embedded atom content increases, the ABF of the bond between the corresponding nickel metal and the OH intermediate decreases, and at the same time, the ELA between its d orbital and the OH species HOMO increases, resulting in a decrease in OHBE , and the alkaline HOR catalytic activity of OHBE and nickel catalysts with different oxygen intercalation contents shows a "volcanic" relationship. Thus, we elucidated the important role of moderate OHBE on the kinetics of alkaline HOR reaction.

Background introduction

Currently, in the research on improving the intrinsic activity of nickel-based alkaline HOR catalysts, doping and alloying strategies are used to control the electronic structure of nickel-based catalysts to weaken the hydrogen binding energy (HBE) of the nickel metal surface, or through Introducing oxygen-loving sites to enhance the oxygen-hydrogen binding energy (OHBE) on the nickel surface is currently a traditional strategy to improve its catalytic activity. Although these strategies have improved the alkaline HOR catalytic activity of nickel metal to a certain extent, they are still far behind PGM catalysts. The main reason is that these synthetic strategies face the technical bottleneck of being unable to achieve optimal control of the electronic structure of the macro-control of the geometric structure of , and thus cannot obtain the optimal optimization of the thermodynamic adsorption energy (OHBE and HBE) of the intermediate , especially for OHBE control. The degree of inaccuracy greatly hinders the maximization of the intrinsic activity of nickel-based catalysts. In addition, the adsorption thermodynamics of intermediate is closely related to the electronic structure of the catalyst. For the electronic structure of catalyst , the antibonding orbital filling degree (ABF) and the degree of molecular orbital overlap are two key factors that constitute the electronic structure of the catalyst. Appropriate molecular orbital hybridization and ABF are the keys to obtaining optimal adsorption energy for reaction intermediates. However, they are often ignored in the process of regulating electronic structure by traditional strategies, which greatly hinders the precise regulation of electronic structure.

Highlights of this article

. Combining molecular orbital theory and d band center theory, a strategy for oxygen insertion through the nickel surface layer is designed, while optimizing the antibonding orbital filling degree of the interaction between nickel metal and OH species and the energy level matching between the two. Achieve precise control of nickel electronic structure and directional optimal control of OH binding energy (OHBE).

. Combining molecular orbital theory and d band center theory, a strategy for oxygen insertion through the nickel surface layer is designed, while optimizing the antibonding orbital filling degree of the interaction between nickel metal and OH species and the energy level matching between the two. Achieve precise control of nickel electronic structure and directional optimal control of OH binding energy (OHBE).

. Combining DFT calculations and experiments, explore the structure-activity relationship between the electronic structure of catalysts with different surface oxygen embedded atom contents and alkaline HOR performance, and construct the "volcano" relationship between OHBE and alkaline HOR activity to clarify the moderate The important role of OHBE in alkaline HOR kinetics.

. Combining DFT calculations and experiments, explore the structure-activity relationship between the electronic structure of catalysts with different surface oxygen embedded atom contents and alkaline HOR performance, and construct the "volcano" relationship between OHBE and alkaline HOR activity to clarify the moderate The important role of OHBE in alkaline HOR kinetics.

Graphical analysis

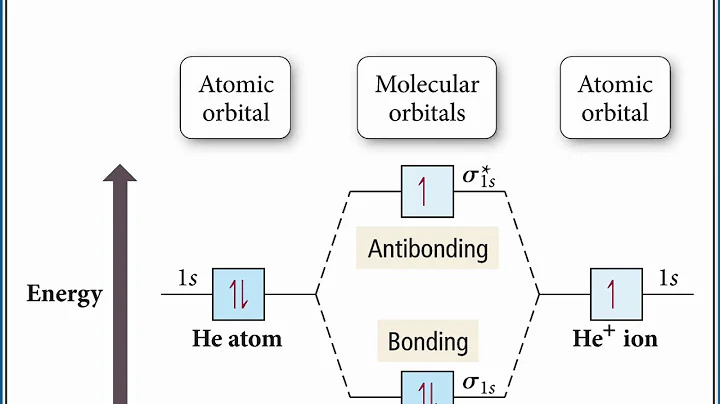

As shown in Figure 1 (a), since the highest occupied molecular orbital (HOMO) of OH- ions has a lower energy level, while pure Ni metal has a higher 3d orbital energy level, so that both The orbital energy level difference (Δ) between them is large, resulting in a relatively low orbital energy level matching (ELA). According to molecular orbital theory, lower ELA will lead to smaller energy level splitting when couples between orbitals, thereby hindering the formation of *OH species.Therefore, lowering the energy level of the 3d orbital at the surface Ni site to increase the ELA between it and the adsorbate HOMO orbital is necessary to enhance *OH adsorption. However, according to Hammer-Nørskov's d energy band model, the downward shift of the surface Ni metal 3d orbital usually leads to an increase in antibonding orbital filling (ABF), so the chemical adsorption of *OH is expected to be weaker, which is consistent with the adsorption of ELA The effects of intensity are conflicting. Therefore, in order to directionally and controllably enhance the adsorption strength of *OH intermediates to accelerate alkaline HOR kinetics, suitable strategies need to be developed to synergistically regulate the competitive effects between ELA and ABF. In this case, increasing the oxidation state of surface Ni atoms through oxygen intercalation is expected to reduce the surface Ni metal d band center, improve the ELA between it and the adsorbate HOMO orbital, and reduce the 3d electrons of Ni metal. Reduce the degree of ABF (Fig. 1b). In addition, according to the Sabatier principle, in order to prevent Ni from being over-oxidized, if the oxygen intercalation can only occur within a few atomic layers on the surface of the Ni metal catalyst, the internal metal core can also offset the oxygen intercalation to a certain extent by using its substrate effect. A severe impact on the electronic structure of the metal site, thereby providing an appropriate degree of ELA and ABF (Fig. 1c), is conducive to moderate *OH adsorption and optimal alkaline HOR activity.

Figure 1. (a-c) Orbital coupling schematic diagram between the HOMO orbital of the OH- anion and the 3d energy band of the Ni metal on the catalyst surface. ψNi-OH and ψNi-OH* are the bonding orbitals (orange) and antibonding orbitals (gray) respectively produced by the energy level splitting when the Ni-OH bond is formed. EF represents the Fermi energy of the system. The inset is the atomic model of the envisioned electrocatalyst, with Ni and O atoms represented in silver and red, respectively. (d) Schematic diagram of the secondary adjustment of the coupling strength between the 3d energy band of the surface Ni metal and the HOMO orbital of the OH- anion (i.e., the adsorption strength of the *OH intermediate).

used high-resolution transmission electron microscopy (HRTEM) to characterize the morphology of the Ni@Oi-Ni nanocatalyst. Subsequently, in order to further analyze the atomic arrangement and element distribution of Ni@Oi-Ni, atomic-level aberration corrected high-angle annular dark field scanning transmission electron microscopy (HAADF-STEM) was used to characterize it. The analysis results show that in the first three layers of atoms on the Ni surface, a lattice with slight deformation fluctuations can be observed. Subsequently, we perform linear intensity profile analysis on the two rectangular areas I and II along the direction of the yellow dotted line. As shown in Figure 2g, for the nickel surface region, the interplanar distances of the first three adjacent layers are 2.21 Å and 2.25 Å, respectively, which is larger than the average interplanar distance of the internal [111] plane (2.03 Å) (Figure 2h). We speculate that the extended interplanar spacing in the first two atomic layers of the nickel surface may be caused by the embedding of oxygen atoms . Subsequently, electron energy loss spectroscopy (EELS) was used to further study the chemical microstructure of Ni@Oi-Ni. The EELS spectrum illustrates the possibility of oxygen atoms embedded within two atomic layers on the nickel surface.

Figure 2. (a, b) HAADF-STEM images of Ni@Oi-Ni. (c) Corresponding fast Fourier transform (FFT) diffraction pattern. (d) Atomic-scale resolution ADF-STEM image of Ni@Oi-Ni projected along the [011] zone axis. The blue atoms are the atomic model of the Ni crystal phase of the fcc structure. The rectangular areas represented by I and II are both Ni (111) planes, which represent the nickel surface layer and the nickel core phase respectively. The corresponding amplified areas are (e) and (f) Corresponding image. Pictures (g) and (h) are the linear intensity profile analysis diagrams along the yellow line direction in the two rectangular areas I and II respectively. (i) ADF-STEM image of Ni@Oi-Ni nanoparticles. (j-m) EELS spectra of C, Ni, O and elemental composites. (n) ELNES spectrum of Ni. (o) ELNES spectrum of C. (p,q) Schematic diagram of the atomic model of Ni@Oi-Ni.

used synchrotron radiation X-ray absorption spectroscopy (XAS) to further explore the atomic local structure of the sample.The XANES spectrum shows that metallic Ni is the main form of Ni@Oi-Ni, and the embedded O in the surface layer results in the existence of the Ni-O coordination bond with higher symmetry on the Ni surface. Extended X-ray absorption fine structure (EXAFS) spectroscopy was further used to determine the local chemical configuration around the Ni site, and information such as the coordination number and bond length around the nickel atoms were obtained through data fitting. XANES and EXAFS analysis results show that Ni@Oi-Ni has metallic Ni properties, and there is an O-embedded coordination environment on the Ni surface, which is consistent with the TEM results.

Figure 3. (a) Ni K-edge, inset is enlarged front edge XANES region. (b) Average oxidation state of different samples. (c) EXAFS spectra of Ni@Oi-Ni, nickel sheets , NiO and Ni. (d,e) Corresponding EXAFS data fitting. (f) wavelet transform diagram of four samples.

The HOR performance of all samples was tested using a standard three-electrode system, using a rotating disk electrode (RDE) in hydrogen saturated 0.1 M KOH solution. After normalizing the mass of nickel in the electrode, the mass activity jk,m of Ni@Oi-Ni at a potential of 50 mV is obtained. As shown in Figure 4(c,d), the jk,m of Ni@Oi-Ni at 50 mV potential is 85.63 mA mgNi-1, which is approximately 40 times that of the Ni nanocatalyst (2.26 mA mgNi-1), and almost It exceeds all the most advanced nickel-based HOR catalysts reported so far, fully demonstrating the excellent catalytic performance of the Ni@Oi-Ni catalyst. Furthermore, after normalizing the electrochemically active area, the specific activity (j0,s) of the sample was obtained. As shown in Figure 4(e), the j0,s of Ni@Oi-Ni is 0.72 mA cmNi-2, which is approximately 6 times that of the Ni nanocatalyst (0.13 mA cmNi-2) and exceeds most of the reported state-of-the-art The Ni-based HOR catalyst is even higher than some Pd-based catalysts, fully demonstrating the excellent intrinsic activity of Ni@Oi-Ni. At the same time, the Ni@Oi-Ni catalyst shows excellent stability and strong CO tolerance.

Figure 4. (a) Alkaline HOR polarization curves of Ni@Oi-Ni, Ni and commercial Pt/C catalysts. (b) The relationship between jk and potential of the three samples is obtained by fitting the Butler-Volmer equation. (c) Comparative histogram of mass activity (jk,m) and specific activity (j0,s) of Ni@Oi-Ni and Ni. (d) Comparison of jk,m between Ni@Oi-Ni and reported advanced alkaline HOR catalysts. (e) Comparison of j0,s between Ni@Oi-Ni and reported advanced alkaline HOR catalysts. (f, g) Stability test of Ni@Oi-Ni catalyst. (h) Comparison of HOR polarization curves in H2-saturated 0.1 M KOH solution before and after chronoamperometry testing. (i) Chronoamperometric test at 0.05 V (Vs RHE) potential in H2-saturated 0.1 M KOH solution containing 100 ppm CO.

Based on atomic resolution ADF-STEM characterization, EELS and XAS characterization, we established and optimized the theoretical model of Ni@Oi-Ni catalyst (Figure 5a-c). As shown in Figure 5(d), we analyzed the 3d orbital projected density of states (d-PDOS) of the surface Ni metal in different catalysts to trace the dependence of its electronic structure on the oxygen embedded content. Figure 5(e) shows that from Ni to Ni@Oir-Ni, the d band center (εd) of the surface Ni metal site gradually moves downward. Compared with the rather low OH-HOMO orbital energy level (-3.08 eV), the downward shift of εd leads to a linear decrease in the energy level difference (Δ) between the surface Ni metal 3d orbital and the OH-HOMO orbital, indicating that the difference between the two ELA increases between. In addition, we performed crystal orbital Hamiltonian population (COHP) analysis on the Ni-O(OH) bonds on the surfaces of different catalysts (Fig. 5f). As shown in Figure 5(g), as the embedded oxygen content increases, εABO-εBO gradually increases, indicating that the energy level split between the bonding orbital and the antibonding orbital gradually increases, while the ABF gradually decreases.

Figure 5. (a-c) Theoretical calculation model of Ni@Oi-Ni catalyst. (d) Calculated d-PDOS (filled area) and fitted d-PDOS (dashed line) for surface Ni metal atoms in pure Ni metal, Ni@Oid-Ni, Ni@Oi-Ni and [email protected] cyan horizontal dotted line indicates the d band center (εd) of the surface Ni metal. (e) The changing trend of the εd of the surface Ni metal atom and the energy level difference (Δ) between the εd of the surface Ni metal atom and the HOMO orbital energy level of the OH- anion relative to the oxidation state of the surface Ni metal atom. (f) Crystal orbital Hamiltonian population (COHP) analysis of Ni-O(OH) bonds. EF stands for Fermi level. (g) The changing trend of the energy level split value (εABO-εBO) between the bonding orbital and the antibonding orbital and the filling degree of the antibonding orbital (ABF).

CO stripping experiments show that as the oxygen embedded content increases, the *OH intermediate adsorption intensity of the catalyst gradually increases, which is consistent with the DFT calculation results. Figure 6(c) shows that there is a good volcano-type relationship between j0,s and OHBE. This volcano-type "structure-activity relationship" conforms to the Sabatier principle, that is, it has neither too strong nor too weak adsorption strength for reaction intermediates. Catalysts tend to have the best catalytic activity. Finally, we calculated the free energy diagrams of the alkaline HOR process on Ni and Ni@Oi-Ni to analyze their reaction thermodynamics. The calculation results show that the free energy change (ΔGRDS) of the RDS reaction of Ni@Oi-Ni is only 0.36 eV, which is much lower than the RDS free energy change (0.57 eV) of the pure Ni metal catalyst . Moreover, the activation energy barrier of the water formation step on Ni@Oi-Ni is much lower than that on Ni metal, which fully demonstrates that Ni@Oi-Ni has faster reaction kinetics. The alkaline HOR catalytic mechanism diagram of Ni@Oi-Ni is shown in Figure 6f. The oxygen intercalation of two atomic layers on the surface endows the nickel nanocatalyst with moderate OHBE and HBE on the surface, which is conducive to accelerating the alkaline HOR reaction rate.

Figure 6. (a) CO stripping experimental tests of pure Ni metal, Ni@Oid-Ni, Ni@Oi-Ni and Ni@Oir-Ni catalysts. (b) The changing trend of the anode peak position (Epeak) and the *OH adsorption energy (OHBE) calculated by DFT in the CO stripping experiment. (c) Volcano relationship plot between ECSA normalized exchange current density (j0,s) and catalyst surface OHBE. (d) Free energy path diagram of the alkaline HOR reaction process on pure Ni metal and Ni@Oi-Ni catalyst. (e) Hydrogen binding energy (HBE) of different catalyst surfaces. (f) Schematic diagram of the alkaline HOR catalyst mechanism of Ni@Oi-Ni.

Summary and Outlook

In this work, we combined molecular orbital theory and Hammer-Nørskov's d-band model to design a method to precisely adjust the electronic structure of Ni metal sites through a surface oxygen embedding strategy to achieve directional regulation of OHBE. The design strategy synergistically regulates the ELA between the OH adsorbate HOMO orbital and the surface Ni metal site d orbital as well as the ABF after the two are bonded. Experimental results show that the Ni@Oi-Ni catalyst has excellent alkaline HOR performance, with a mass activity as high as ~85.63 mA mg-1, which is ~40 times higher than the performance of pure Ni metal catalysts. It is the best non-catalytic catalyst reported so far. One of the precious metal alkaline HOR electrocatalysts. In addition, a volcano-type correlation between *OH binding strength and HOR activity was established based on experimental and theoretical results, emphasizing that OHBE should be neither too strong nor too weak to promote a substantial increase in alkaline HOR activity. This work not only identifies the key role of OHBE in promoting alkaline HOR kinetics, but also provides new design principles for designing high-performance alkaline HOR electrocatalysts by precisely tailoring the electronic structure, i.e., synergistically regulating ELA and ABF.

![Ivy Shao (邵雨薇) - Stars and Moon (星月) (Sweet Combat/甜蜜暴击) - [Chinese|Pinyin|English] lyrics - DayDayNews](https://i.ytimg.com/vi/-UclXdelFVI/hq720.jpg?sqp=-oaymwEcCNAFEJQDSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLBJma4bG-TwK2rtGvhDh8bM2ui5cA)