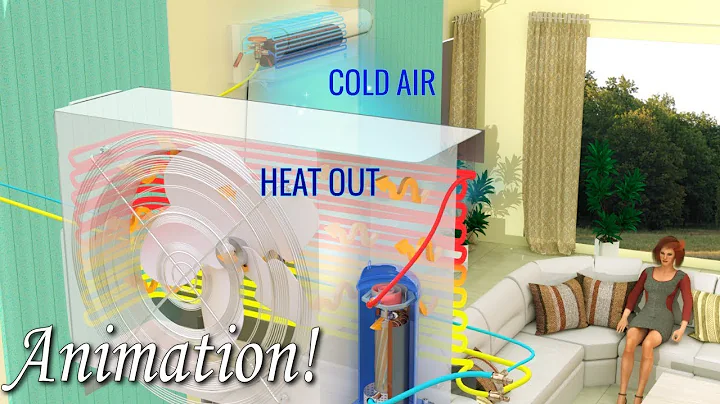

In the evaporator , the heat of the cooled medium is transferred to the refrigerant through the heat transfer wall, causing the liquid refrigerant to absorb heat and vaporize. The physical state change of the refrigerant in the evaporator is actually a boiling process, which is customarily called evaporation. The heat transfer effect in the evaporator is also affected by factors such as the heat transfer coefficient on the refrigerant side, the thermal resistance of dirt on the heat transfer surface, and the heat transfer coefficient on the cooled medium side, just like the condenser .

1. Influence of the physical properties of the refrigerant liquid

The thermal conductivity, density, viscosity, surface tension and other related physical properties of the refrigerant liquid have a direct impact on the boiling heat transfer coefficient.

A refrigerant with a large thermal conductivity has a small thermal resistance in the heat transfer direction and a large boiling heat transfer coefficient.

Under normal working conditions of the evaporator, the temperature difference between the refrigerant in the evaporator and the heat transfer wall is generally only 2~5°C. The intensity of the convective heat transfer depends on the degree of convective movement of the refrigerant liquid during the vaporization process. . During the boiling process, the movement of bubbles inside the liquid disturbs the liquid, which increases the possibility of contact between various parts of the liquid and the heat transfer wall, making it easier for the liquid to absorb heat from the heat transfer wall and the boiling process faster. The refrigerant liquid with smaller density and viscosity will be more strongly disturbed by this kind of disturbance, and its convection heat transfer coefficient will be larger.

The greater the density and surface tension of the refrigerant liquid, the larger the diameter of the bubbles during the vaporization process. The longer it takes for the bubbles to leave the heat transfer wall, the fewer bubbles are generated per unit time, and the heat transfer coefficient is Small.

Generally speaking, the thermal conductivity of Freon is smaller than that of ammonia, and its density, viscosity and surface tension are larger than that of ammonia, so its boiling heat transfer coefficient is smaller than that of ammonia.

2. Influence of the wetting ability of the refrigerant liquid

If the refrigerant liquid has a strong wetting ability on the heat transfer surface, the bubbles generated during the boiling process will have small roots and can quickly break away from the heat transfer surface, and the heat transfer coefficient will also be reduced. Just larger. On the contrary, if the refrigerant liquid cannot wet the heat transfer surface well, the bubble roots formed will be very large, reducing the number of vaporization cores, and even forming a gas film along the heat transfer surface, significantly reducing the heat transfer coefficient.

Several commonly used refrigerants are all wettable liquids, but the wetting ability of ammonia is much stronger than that of Freon.

3. The influence of refrigerant boiling temperature

During the boiling process of the refrigerant liquid, the more bubbles generated per unit time on the evaporator heat transfer wall, the greater the boiling heat transfer coefficient. The number of bubbles generated per unit time is related to the time it takes for the bubbles to leave the heat transfer wall. The shorter this time is, the more bubbles are generated per unit time. In addition, if the diameter of the bubble when it leaves the wall is smaller, the time from generation to departure of the bubble will be shorter.

When the bubble leaves the wall, its diameter is determined by the balance of the buoyancy of the bubble and the surface tension of the liquid . Buoyancy forces the bubbles to leave the wall, while the surface tension of the liquid prevents them from leaving. The buoyancy of the bubbles and the surface tension of the liquid are in turn affected by the density difference (the density difference between liquid and vapor) at saturation temperature. The buoyancy of a bubble is proportional to the density difference. The surface tension of a liquid is proportional to the fourth power of the density difference.

Therefore, as the density difference increases, the surface tension of the liquid increases much faster than the buoyancy of the bubble. At this time, the bubble can only rely on volume expansion to maintain balance, so the diameter of the bubble when it leaves the wall Just big. The size of the density difference is related to the boiling temperature. The higher the boiling temperature, the smaller the density difference at the saturation temperature, the vaporization process will be faster, and the heat transfer coefficient will be larger.

The above shows that in the same evaporator, when using the same refrigerant, the heat transfer coefficient increases as the boiling temperature increases.

4. The influence of evaporator structure

During the liquid boiling process, bubbles can only be generated on the heat transfer surface. The effective heat transfer surface of the evaporator is the part in contact with the refrigerant liquid. Therefore, the size of the boiling heat transfer coefficient is related to the structure of the evaporator. Experimental results show that the boiling heat transfer coefficient on the finned tube is greater than that on the bare tube, and that on the tube bundle is greater than that on the single tube. This is because after adding fins, under the same conditions of saturation temperature and heat load per unit area, the conditions for bubble generation and growth are more favorable than that of light tubes. Due to the increase in the number of vaporization cores and the decrease in bubble growth rate, the bubbles can easily break away from the heat transfer wall. The experimental results also show that the boiling heat transfer coefficient of the finned tube bundle is greater than that of the plain tube bundle. According to some data, at the same saturation temperature, the boiling heat transfer coefficient of Rl2 in the finned tube bundle is 70% larger than that of the plain tube bundle, while that of R22 is 90% larger.

Based on the above analysis, the structure of the evaporator should ensure that the refrigerant vapor can quickly leave the heat transfer surface. In order to effectively utilize the heat transfer surface, the vapor generated after throttling the liquid refrigerant should be separated from the liquid before entering the evaporator, and during operation management, the evaporator should maintain a reasonable refrigerant liquid flow rate.

In addition, the refrigerant contains oil, which also has a certain impact on the boiling heat transfer coefficient, and the degree of impact is related to the oil concentration. Generally speaking, when the oil content of the refrigerant is not greater than 6%, this effect does not need to be considered. When the oil content is larger, the boiling heat transfer coefficient will decrease.

『 statement : This article comes from the Internet. It is not an original article on the hotel engineering exchange platform. The source will be indicated. The reprinted content is only for learning and communication purposes. The views stated do not represent the position of the Hotel Engineering Exchange Platform. The copyright belongs to the original author. If there is any infringement, please contact us to delete it. Thank you