TSMC , SMIC is the leading chip manufacturer in the industry. TSMC has mastered the 5nm mass production process, and SMIC has also successfully achieved 14nm mass production. For the chip manufacturing industry, both are irreplaceable.

Nowadays, the world is facing the problem of core shortage. The two giants have successively received new news and invested more resources to expand production capacity. what does that mean? Can the core shortage problem be solved?

TSMC will build six more 7nm factories

html On September 6, it was reported that TSMC would set up a factory in Kaohsiung . TSMC did not make any comments on this, emphasizing that everything is based on the company's external announcements.TSMC emphasized that with Taiwan as its main base, there are many considerations in choosing a factory location. It does not rule out any possibility. It will maintain its past pace of factory expansion and continue to cooperate with the Administration to evaluate suitable semiconductor locations in Hsinchu , Taichung and Kaohsiung. Land for building factories.

TSMC used to invest as far south as Tainan in Taiwan Province. Now it is rumored that it will settle in Kaohsiung. The relevant authorities are unwilling to respond to the matter, fearing that mutual trust will be affected after the news is exposed. The person in charge of investment promotion said that this is related to the manufacturer's industrial layout and it is not appropriate for relevant departments to discuss it. If there is a clear progress, it should be announced by TSMC.

CNPC Kaohsiung Refinery will close down at the end of 2015, and the renovation site area is 169.5 hectare. The news came out that in order to win TSMC to settle in Kaohsiung, the relevant authorities took a multi-pronged approach to solve the problem of setting up a factory. They locked the CNPC Kaohsiung refinery base and signed an administrative contract with CNPC to handle it on their behalf, shortening the soil remediation period to 2023. Finish. Based on this estimate, TSMC will settle in Kaohsiung in two years at the earliest.

If the plan is successfully implemented, it means that TSMC will become the dominant player in advanced technology wafer foundry in the future, once again raising industry barriers. But three or five years later, the market demand for advanced processes will become increasingly strong. TSMC will have unparalleled dominance on the 7nm node with its large-scale production capacity.

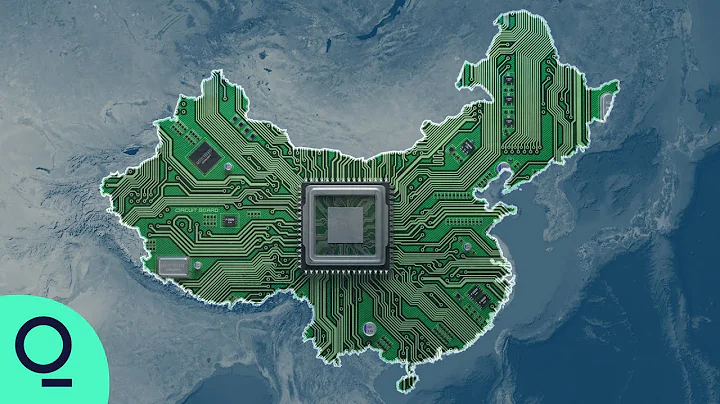

SMIC takes the lead in chip localization

html On September 3, SMIC, the “first brother” of domestic chip foundry, released two blockbuster “bombs”, namely Zhou Zixue resigned as chairman of the company and invested 570 million billion to build a factory in Shanghai. The news of the construction offactory can be said to be a sensation in the industry. After all, this is SMIC’s third expansion of 12-inch wafer production capacity since the end of last year.

SMIC said that the project will greatly promote the company's expansion of production scale and nanotechnology services. At present, the core shortage is still hot, and SMIC's production expansion plan is expected to drive the development of domestic semiconductor equipment and promote the process of chip localization.

As one of the world's leading integrated circuit wafer foundry companies, SMIC has expanded its 12-inch wafer production line three times in less than a year since the end of last year.

The chip shortage is getting worse, and the difficulty in finding a chip in the market continues to rise. Those who paid the highest price from the beginning can't buy it even if they have money now, and chip production capacity has always been in short supply.

SMIC, as a leading inland professional wafer foundry company, mainly provides customers with integrated circuit wafer foundry and supporting services for a variety of technology nodes and different process platforms from 0.35μm to 14nm. It can be said that amid this global chip shortage, the explosion of market demand, and the surge in production capacity of major factories, SMIC has fully tapped the market demand. On the one hand, it has continued to expand and build new factories to meet production needs; on the other hand, increasing production has enabled It has made "a lot of money" in the chip field.

Although we cannot break through the 7-nanometer process barriers established by TSMC in a short period of time, we can try our best to maintain our revenue in the 28-nanometer chip market. It is worth mentioning that in order to contain the development of TSMC and at the same time increase its share in the Chinese chip market, South Korean Semiconductor has increased its support for mainland Chinese chip manufacturers. For example, Samsung has increased financial support for the NAND chip production base invested and built in Xi'an.