The Expo original center created by Puyuan Sweater Innovation Park. Reporter Li Zhe took a photo of a corner of the Puyuan Sweater Innovation Park. Photographed by our reporter Li Zhe

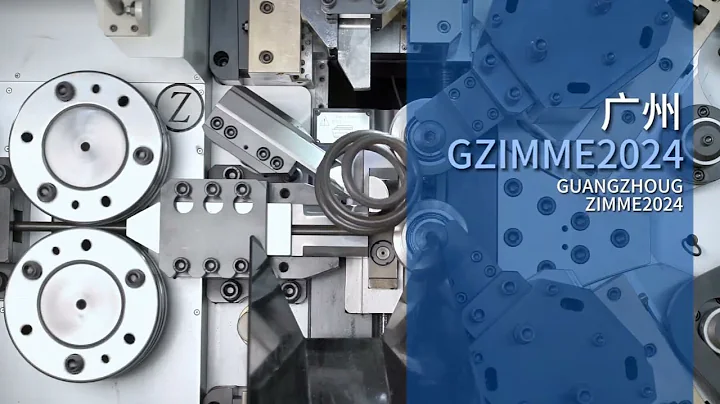

nd gear lathe operates the integrated seamless machine in the intelligent weaving workshop. Photographed by our reporter Li Zhe

Reading tips

Not long ago, the United States implemented new tariff measures on my country’s exports, including the textile industry. As an "old" traditional industry, the profit margins of the textile industry are already limited. Will the imposition of tariffs have a big impact on enterprises? In Jiaxing, Zhejiang Puyuan Sweater Innovation Park, many foreign trade companies have not only resolved the risks caused by rising tariffs, but also gained more benefits by improving product competitiveness, expanding into new global markets, and improving customer service capabilities. Many customers and orders. Please follow the Economic Daily reporter into the Puyuan Sweater Innovation Park to find out.

html On the morning of September 8, in the hotel in the town’s industrial park, there was a long queue in front of the omelette window in the cafeteria, including many businessmen who spoke Japanese and Korean. Puyuan Town, the “famous woolen sweater town in China” located in Jiaxing, Zhejiang Province, ushered in the peak season for woolen sweater purchasing early.html "Small goal" of 71 million yuan

Products are highly competitive and there is no need to worry about running out of business

"My goal is at least 100 million yuan!" Liang Wenmei is not Wang Jianlin. Four years ago, she just received her first job in her life. Foreign trade order - 500 woolen sweaters. For the past two years, her foreign trade company had not made a penny. But in Liang Wenmei's eyes, the company's annual turnover of 100 million yuan is just a small goal.

html More than 120 years ago, the newly married couple Liang Wenmei and Su Mingyuan left their hometown in Sichuan for Guangzhou with 300 yuan in their arms, and began to work hard. They have knitted sweaters in factories, played with looms in rental houses, and opened stalls in wholesale markets.In 2005, Liang Wenmei keenly discovered that a group of customers suddenly appeared in the Guangzhou market. They spoke with the same accent and picked up an amazing amount of goods. After several inquiries, Liang Wenmei heard the name of the Zhejiang town "Puyuan" for the first time. She immediately decided to leave the old market of Guangzhou and go to the new market of Puyuan to make a career in the world. After

opened a store in Puyuan for several years, the troubled Liang Wenmei had a new idea - "I want to do global business and sell woolen sweaters abroad." In 2013, Liang Wenmei used all her belongings to establish Zhejiang Kangying Clothing Co., Ltd., which specializes in foreign trade business.

However, Liang Wenmei, who has no foreign trade experience at all, has been drinking from the northwest for two years. The turning point for

appeared in 2015. "I want to thank my first customer, who taught me how to do foreign trade business." At the Canton Fair that year, Liang Wenmei received her first order from Canada, 500 woolen sweaters, worth more than 20,000 yuan. Yuan. Liang Wenmei, who was used to being a self-employed person, did not know what a proforma invoice was and had never seen any formal form. "I quickly saved every email and form sent by Canadian customers and learned from them. This is how business is learned." Liang Wenmei said.

Soon, Liang Wenmei brought her business to the United States. "In 2015, I received an order for 500 pieces of from the American company TJX. This is a big brand. Later, our cooperation became more and more frequent. Now they give me large orders of hundreds of thousands of pieces a year. The volume will definitely continue to increase in the future." Liang Wenmei told reporters that since then, she has done more and more business with American customers. Last year, orders from the United States accounted for 60% of the company's turnover of 16 million yuan.

When a reporter asked whether she was worried about the stability of her customers and profit prospects in the face of the increase in tariffs, the cheerful Liang Wenmei said loudly: "If taxes are raised, they will be raised. It won't have much impact on me, and I'm not worried either. The first thing is "My products have unique styles, and I spend a lot of money on style development every year. It is difficult for Southeast Asian countries to produce these styles, and American customers cannot change suppliers."

It is because their products are not homogeneous. route and strong competitiveness, so Liang Wenmei also has a stronger voice when negotiating with customers."Why am I not worried? The second point is because all my foreign trade orders are traded on an 'FOB' basis. In other words, I only need to send the goods to the port in Shanghai and the task is completed. Outside the Shanghai port Shipping costs, tariffs and other prices have nothing to do with me," Liang Wenmei said.

So, who will bear the additional tariff costs? Will American merchants reduce their orders for the coming year due to lower profits? "They had no choice but to raise prices, and in the end it was American consumers who paid for the tariffs." Liang Wenmei told reporters that not only did she not lose any of her American customers, she also added many new ones. In the first half of this year, her company even achieved year-on-year sales. An impressive performance of 80% growth.

html On August 13, at the clothing exhibition in Las Vegas, Liang Wenmei's harvest was unprecedentedly rich. "Merchants are very interested in my products. Many customers placed orders and took samples on the spot. My email response rate has also reached an unprecedented 50%. It is expected that five or six companies will become long-term customers." Liang Wenmei smiled. He said: "When I was working in the bank this morning, I received a call from the United States, saying that he would come to our company in October to review the products. There is great hope for cooperation."In this regard, the troubled Liang Wenmei Not satisfied, new plans have been hatched. In order to be closer to customers, Liang Wenmei just registered a branch in Los Angeles last month, so that she can develop a larger market in the United States.

"The market is so big, no matter what friction occurs, as long as the product is good, there will be no business. I believe that the small goal of 100 million yuan will be achieved in a short time." Liang Wenmei laughed and told reporters: "Everything is just now Let's start!"

Three groups of Japanese customers came in one week.

Exploiting emerging markets and taking the brand development route

I couldn't find a seam in a sweater. In the sample room of Jiaxing Huali Sweater Technology Development Co., Ltd., the reporter found that the sweaters here can be worn on both sides, because there are no seams on the inside and outside of the clothes.

walked into the intelligent weaving workshop of Puyuan Sweater Innovation Park, and the reporter understood the whole story. "Traditionally knitting a sweater involves first knitting two sleeves and the front and back placket on a flat knitting machine, and then the seamstress hand-sews the four sweater pieces together, so there will naturally be seams. With the use of the most advanced one-piece molding With a seamless machine, as long as the pattern maker writes the program and the wool is connected, the machine can knit a complete sweater without even a single seam, and then it can be shipped directly.” Manager Shen Xiaoqi told reporters.

has no seams, just one of the advantages of this machine. “Since the manual creasing step is omitted, the use of an all-in-one machine can save labor costs and shorten production time. More importantly, it can avoid the impact of manual operations on quality uniformity, and the added value of the product can be increased by about one-third.” Shen Xiaoqi pointed to the sweaters in the sample room and said: "The sweaters produced by these all-in-one machines can be sold in shopping malls for more than 1,000 yuan, or even more than 2,000 yuan."

Good machines, naturally good prices. The price of this German brand all-in-one machine is as high as 580,000 yuan. Coupled with the high-paying introduction and training of pattern makers and lathe workers, a large-scale workshop requires at least tens of millions of yuan in investment.

"This investment is very worthwhile. These new clothes of mine are very popular in the Japanese market and have already received many orders." Shen Xiaoqi told reporters that in a few days, she will take these sample clothes to Europe to have a look. Market Reaction.

Shen Xiaoqi, who has a baby face, has been in the sweater foreign trade industry for almost 10 years. In the first few years, the orders she received mainly came from large American supermarkets such as , Wal-Mart, and . Most of them were "volume-based orders." These orders were large in quantity, low in profit, and very price sensitive. Later, as domestic labor costs and raw material prices increased, such orders gradually moved to countries such as Bangladesh , Vietnam , Cambodia , etc.

In 2015, Shen Xiaoqi began to form a research and development team, recruit designers, invest in building production houses, bid farewell to the era of "price wars", and instead focus on product quality.While slowly giving up on "volume-based orders" in the United States, Shen Xiaoqi has obtained many "small but refined" high-quality orders in new markets such as Japan and Italy, and profit margins have also increased accordingly.

"Currently, the proportion of our company's U.S. orders has dropped to more than ten percent. This increase in U.S. tariffs will have an impact on us, but we can bear it." Shen Xiaoqi told reporters that after learning about the additional tariffs, she and The American customer communicated, but the result was not ideal. The other party asked her to bear most of the tariff costs.

"Fortunately, we have already begun to transform, improve product quality, and develop emerging markets. Just this week, three groups of Japanese customers came to our company to select samples. They were all interested in products with relatively high added value." According to Shen Xiaoqi According to reports, the turnover of Huali Sweater Company last year was around 60 million yuan. Although some orders this year will be affected by the additional tariffs imposed by the United States, fortunately, the share and profit margins in other markets are constantly increasing, so this year’s business is expected to be Revenues are not down, but about the same as last year. While

continues to develop new foreign trade markets, Shen Xiaoqi also sets his sights on the country. "Domestic sales and foreign trade markets are completely different. To do foreign trade OEM, you only need to produce according to the order requirements and do not need to face consumers directly. Domestic sales, on the other hand, put forward higher requirements for brand, design and service capabilities." Shen Xiaoqi said , after the transformation experience in the past few years, she has become more and more confident in her products. She registered two brands last year and is ready to start digging into the domestic market and take the brand development route.

During lunch time, Shen Xiaoqi was not idle. She and her sister, who had returned from studying in Milan, Italy, kept "pointing" at the mobile phone screen, studying how their online store could be improved to make their products and brands more popular. Impress consumers.

"I won't do it at this price"

Role changes bring increased voice and bargaining power

Near noon, Shen Qiang sat on the boss's chair and looked out. The floor-to-ceiling window was bright and open, and what made him feel even more comfortable was his mood. In 2016, he founded Tongxiang Xindishang Fashion Co., Ltd., with a turnover of 11 million yuan that year, soaring to 43 million yuan in the second year, and doubling again in the third year, reaching 97 million yuan. In the first eight months of this year, the company's revenue has already exceeded 100 million yuan. The "rocket" growth performance of

is indeed surprising. With questions, the reporter walked into Shen Qiang's company. The open space is filled with plastic models wearing fashionable clothes and design drawings on the wall, giving off a strong fashion atmosphere.

"Market fluctuations are not that scary. We have the strength to choose high-quality customers." Shen Qiang told reporters that before 2016, when he worked in other foreign trade companies, he mainly took low-price orders from the United States, purely competing for price, and the gross profit margin was even As low as only 5%. "At that time, the company lacked product development capabilities and produced everything to order. In order to earn an extra 50 cents or 1 yuan, it took huge risks. If there was a slight disturbance, it might be a loss-making business. If something happened at that time When it comes to trade friction, many companies will go bankrupt."

saw this. When he founded his own company, Shen Qiang was determined not to accept low-quality orders, but relied on "directional design" to gain a foothold. Different from original design, "directional design" emphasizes more on customer service capabilities.

"For a large customer, we will have a team of at least 10 people. As long as the customer puts forward directional requirements, we will combine the latest fashion trends and propose a variety of design solutions, including styles, colors, material selection, etc." Shen Qiang He said that they have extended from the downstream production link to the market research and design fields. In this way, they are not just a simple OEM role, but have become a partner of customers.

foundries can be replaced at any time, and partners are not easy to find. The change in role has brought about an increase in voice and bargaining power. "It used to be that the customer had complete control over the process of sample collection, proofing, quotation, and production. Now, we have become participants in multiple links, and our right to speak has naturally increased. If the other party lowers the price for me, I can do it without any hesitation." He said bluntly: 'I won't do it at this price,'" Shen Qiang told reporters.

The apparel industry may seem traditional, but it requires quick response and innovation. Fashionable styles are fleeting and update very quickly. If there is no rapid response in design and production, there will be no competitiveness. "Take my client ZARA as an example. It is a typical example of fast-selling fashion. If it takes a month or two to make a sample like in the past, all trends have passed. No matter how low the price is, the other party will not cooperate. "Shen Qiang said that relying on the local complete industrial chain and strong service capabilities, his company can produce sample clothes for customers to choose from as soon as one day.

"Unlike Chinese companies, the production cycle of companies in Southeast Asian countries is relatively long. First of all, in terms of raw materials, Southeast Asian countries generally only stock conventional yarns. Most of the yarns, especially fashion ones, have to be imported from China. This will add a lot of transportation time. Secondly, the management level and worker efficiency of our company are significantly higher," Shen Qiang said, which is also an important reason why my country's textile industry is irreplaceable.

Develop your own skills and be able to eliminate risks. "Our company's advantages lie in this. The country's tax cuts and fee reductions are also very large, and the Sino-US economic and trade frictions have little impact. The US order was originally shipped in September, but after receiving the news of the additional tariffs, the customer notified us Ship the goods in advance, instead of shipping by sea, and the extra shipping cost will be borne by the other party. In the end, it is the American consumers who pay the price. The clothes originally sold for US$10 will probably increase to US$11,” Shen Qiang said.

"But for ordinary processing plants that engage in price wars, the impact will be great. They cannot afford the new tariffs. If U.S. importers are hit by tariffs and suffer poor operations or even bankruptcy, it will lead to malicious discounts or cancellation of orders. , the risk is even greater.” Shen Qiang believes that this is actually a reshuffle and a warning to the industry. If backward production capabilities with poor management, high energy consumption, and no core competitiveness are eliminated, the entire industry will go downhill. A higher quality development path.